ER 7075 Aluminium Welding Wire

Request a Quote

Welding Consumables

Aluminimum-zinc filler metal for MIG and TIG welding of 7075 aluminium alloy in the T6 temper

- Standard: GB/T3190-2020

Chemical Composition (%)

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al | Others | |

| Each | Total | |||||||||

| ≤0.40 | ≤0.50 | 1.2-2.0 | ≤0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | ≤0.20 | Rest | ≤0.05 | ≤0.15 |

Features

- Designed for welding high-strength 7075 aluminium alloy, which is known for its excellent mechanical strength and hardness

- Due to its high zinc content, welding this alloy presents challenges such as potential brittleness in the weld zone and reduced joint strength compared to the base metal

- To avoid defects such cracking, it’s important to carefully control welding parameters such as heat input and travel speed

- For best results, welding should be performed while the material is in the T6 temper condition to maintain structural strength and integrity

Available Sizes

- Welding wire: 1.2/1.6/2.0/2.4/3.0/3.2/4.0mm

- Spool: D270 (7kg)

Applications

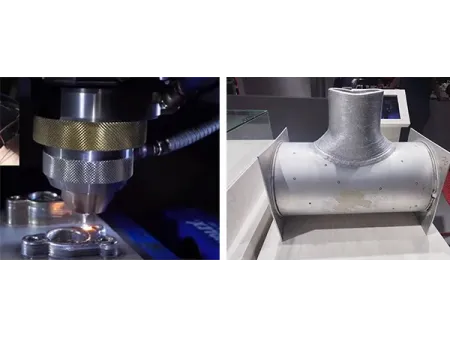

- Commonly used in the aerospace industry for welding structural components and high-strength fittings

- Suitable for mould and fixture fabrication, especially in setups requiring durable and lightweight structures

- Ideal for producing parts that operate under high stress in mechanical systems.

- Also used in specialized products such as high-end aluminium bicycle frames.

Packaging

- MIG wire diameter: 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm

- Package: D300 (9kg/spool), D270 (7kg/spool)

- TIG wire diameter: 2.0mm, 2.4mm, 3.0mm, 4.0mm

- Package: 1000mm length (10kg/box)

- TIG wire diameter: 1.6mm, 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm

- Coil inner diameter: D450mm, D300mm

- Package: 10-17kg/coil

Recommended Welding Method

ER 7075 welding wire is compatible with both MIG and TIG welding. It should be used with alternating current (AC) and pure argon as the shielding gas. Before welding, make sure the base material and welding wire are clean and dry to avoid porosity or defects during the welding