ER 3003 Aluminium Welding Wire

Request a Quote

Welding Consumables

Aluminium-manganese filler metal for MIG and TIG welding of pure aluminium and aluminium manganese alloys

- Standard: GB/T3190-2020

Chemical Composition (%)

| Si | Fe | Cu | Mn | Zn | Al | Others | |

| Each | Total | ||||||

| ≤0.6 | ≤0.7 | 0.05-0.20 | 1.0-1.5 | ≤0.1 | Rest | ≤0.05 | ≤0.15 |

Features

- Aluminium-manganese alloy wire widely used for welding applications that require good corrosion resistance and formability

- Offers slightly higher strength than commercially pure aluminium, but cannot be strengthened by heat treatment

- Its mechanical properties can be improved through cold working; high plasticity in annealed condition, moderate in semi-cold work, and low in full cold work

- Commonly classified as a non-heat-treatable anti-corrosion alloy, though its machinability is relatively poor

Available Sizes

- Welding wire: 0.8/1.0/1.2/1.6/2.0/2.4/3.0/3.2/4.0/5.0/6.0mm

- Spool: D300 (9kg), D270 (7kg), D200 (2kg), D100 (0.5kg)

Applications

- Ideal for welding components that require high plasticity and good weldability

- Commonly used for low-stress load parts exposed to liquid or gas environments

- Suitable for fuel tanks, oil and lubrication pipes, liquid containers, and other deep-drawn parts designed for light-duty performance

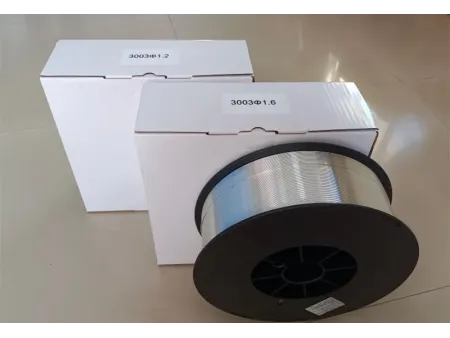

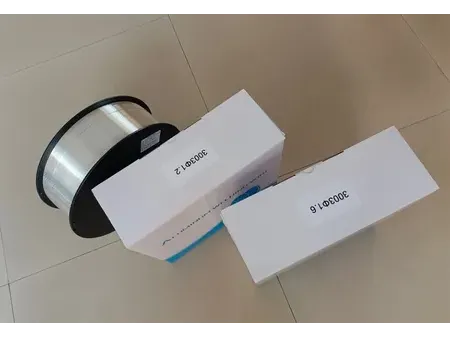

Packaging

- MIG wire diameter: 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm

- Package: D300 (9kg/spool), D270 (7kg/spool)

- MIG wire diameter: 1.2mm, 1.6mm

- Package: drum D660 (100kg/drum)

- TIG wire diameter: 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm

- Package: 1000mm length (10kg/box)

- TIG wire diameter: 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm

- Coil inner diameter: D450mm, D300mm

- Package: 10-17kg/coil

Recommended Welding Method

For best results, this wire performs well with both MIG and TIG welding processes. AC TIG welding with pure argon shielding gas is typically preferred to ensure clean, stable arcs and strong welds. It's important to remove any surface contaminants beforehand and avoid moisture on the workpiece or welding wire, as these can impact welding quality and consistency.