Appearance Inspection Machine

Request a Quote

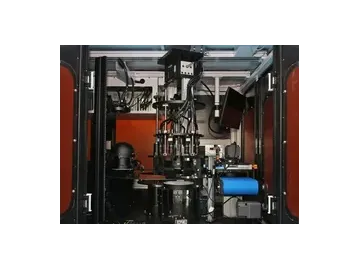

AI visual inspection system for detecting flaws and defects on the surface of various products

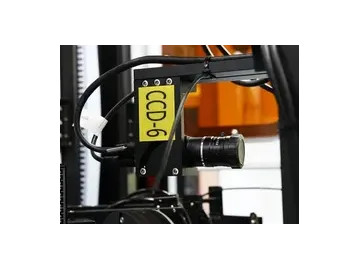

- 10 years of expertise in CCD optical visual inspection

- Equipped with German industrial cameras, U.S. fiber optics, and a fully customized vision system

- Trusted by 12,000 clients, including leading brands like HUAWEI and Wahaha

Working Principle

This AI-powered system compares OK and NG samples using deep-learning algorithms trained directly on your product images. The system can:

- Analyze 200–300 reference images per cycle

- Detect 100 to 2,000 pieces per minute

- Train and adapt to new products within 3 minutes, using real-time CCD imagery to detect even the smallest surface defects

AI automatically learns and updates based on your product’s unique characteristics, enabling consistent and high-speed rejection of flawed items without manual judgment.

Application

The appearance inspection machine is ideal for surface quality control in:

- Metal hardware components

- Ceramic products

- Automotive parts

- Electronic and PCB assemblies

- Jewelry and gemstones

- Screws and fasteners

- Magnetic materials

- Various small industrial parts

Looking to eliminate human error in visual inspection?

Reach out to learn how our AI appearance inspection system can help you maintain flawless quality at scale.