DXD-520C Vertical Weighing Form Fill Seal Machine (10g~2000g VFFS)

Application

The DXD-520C VWFFS machine is a precise and full-automatic packing machine, which has a filling range of 100~2000g. This type of packing machine is commonly applied to the packaging of snacks, chocolate, candies, dried fruits, dried vegetables, sugar, rice, salts, pet food, frozen food, baked food, spaghetti pasta, drug, hardware products, beans, seeds, wood and plastic products, etc.

- Snacks and other products

Packing film

Packing film Packaging bags

Packaging bags

| Model | |

| Packing speed | 15-70bags/min |

| Bag-making Size | (L)80-350mm (W)80-250mm |

| Filling Range | 10-2000g |

| Film Width | 180-520mm |

| Packing Material | OPP/CPP PET/PE/ Laminated film |

| Film Thickness | 0.04-0.08mm |

| Air Consumption | 0.36m3/min 0.6MPa |

| Power Supply | AC220/380V 50/60Hz 3.5kw |

| Machine Dimension | (L)1750×(W)1050×(H)3700mm |

| Machine Weight | 800kg |

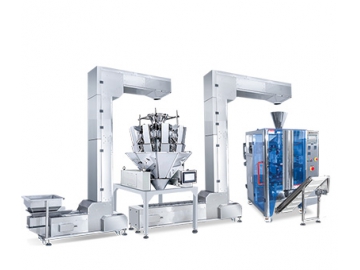

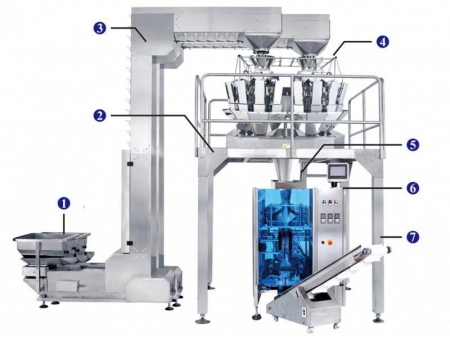

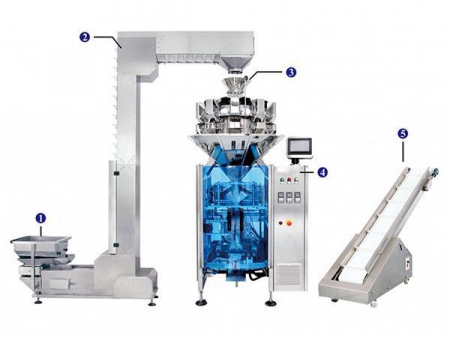

1. Z Shape Bucket Elevator

The Z shape bucket elevator is mainly used for transporting the product material from ground hoppers to multihead weigher, which has a higher efficiency when it works with multihead weigher.

2. Multihead weigher

Multihead weigher is an intelligent and precise weighing system with the customized as 10 heads, 14 heads or 20 heads. Every weigher has a single touch screen and it is very convenient to changing parameters on the screen without any replacement of components when target weight changes. Besides, this weighing system can realize the weight error less than 0.5%.

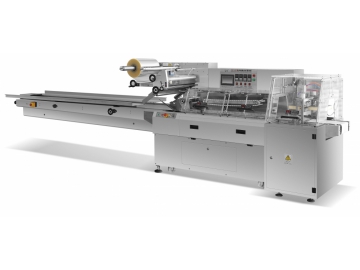

3. Vertical packing machine

When the weighing procedure in multihead weigher is finished, products drops into the hoppers of vertical packing machine. After that, the steps of making of bags, filling of products, sealing, cutting of bags, date imprinting are performed in sequence in the vertical packing machine.

4. Products Conveyor

After the packing procedure is finished, all the finished bags are transported to collecting buckets or the next procedure spot with the help of conveyors.

1. The system adopts multihead weigher, which is a precise weighing system with weighing error of 0.5% and is very convenient to changing target weight with the equipped touch screen.

2. Z shape bucket elevator is convenient for customers to feeding because feeding hopper is on the ground.

3. The packing system adopts the Panasonic AC servo motors ensuring the precise and stable running of machine.

4. The machine is equipped with Weinview touch screen, which is easy learning and convenient to setting the running parameters.

5. This type of packaging machine applies double belt film-drawing system, which has an advantage on the stability of film-drawing procedure.

6. The VFFS machine is equipped with automatic constant temperature heating device, which can keep a stable temperature and the beauty of sealing.

7. Plastic bearing is used in this machine and not need lubricating oil ensuring the safety of products.

8. The machine uses Electro-Optical Sensor System(EOSS) to realize automatic alignment on the packing films and guarantee the same appearance of each bag.

9. When the required width of bags changes, the packing system can change bag maker in 5~10 min without any tools.

10. The machine is equipped with a printer, which can perform the function of printing manufacture date and batch number and so on.

11. The system has a low maintenance cost because of few damageable assemblies.

12. The contact components with products material are made of stainless steel, which can meet the requirement of food manufacture.