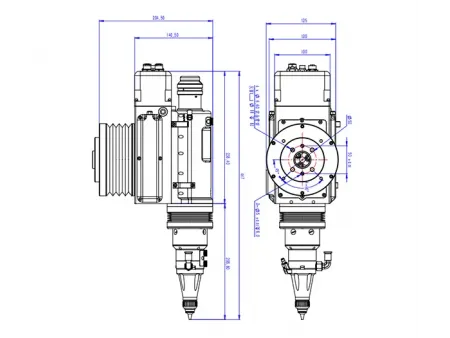

4kW 3D Robotic Laser Cutting Head

LCR04

Auto focus laser cutting head with built-in follower axis for cutting complex 3D shapes

LCR04

Auto focus laser cutting head with built-in follower axis for cutting complex 3D shapes

A common challenge in robotic 3D cutting is to keep the nozzle-to-part distance steady as the path moves over curves and formed sections, while focus adapts to local thickness changes. Our 4 kW 3D robotic laser cutting heads address this with auto focus and a built-in height follower (capacitive standoff control). These features hold the standoff constant on contoured panels and keep cut quality stable as the robot changes angle and speed. The body is compact and well-sealed, so it fits tight robot workspaces. A precise reset mechanism and an anti-collision design protect alignment after minor bumps, which helps production stay consistent.

| Type | Auto Focus 3D Robotic Laser Cutting Head |

| Model | LCR04 |

| Interface Type | QBH |

| Wavelength | 1080±10nm |

| Rated Power | ≤4kW |

| Focal Length | 150mm |

| Collimation Length | 75mm |

| Focusing Range | -24mm~ 20mm |

| Centering Adjustment Range | ±1.5mm |

| Focusing Speed | ≤200mm/s |

| Repeated Positioning Accuracy of Focusing Axis | 0.05mm |

| Focusing Stroke | 12mm |

| Focusing Speed | ≤50mm/s |

| Follow-up Stroke | 27mm |

| Follow-up Speed | ≤250mm/s |

| Auxiliary Gas Pressure | ≤2.5MPa |

| Weight | 7.0kg |

These 3D cutting heads run on five-axis cutting machines and robot cells for automotive body work, fenders and related exterior panels. They handle carbon steel, aluminum, copper, and galvanized sheet with steady edge quality across all.

Closed-loop water cooling at the QBH interface/connector keeps temperature stable and prevents condensation on the optics, so long runs remain consistent.

A three-point conical locating system returns the head to its original position after a bump, so alignment stays accurate.

The integrated follower module (capacitive standoff control) is fully enclosed and lightweight, keeping dust out while tracking surfaces quickly for precise, high-speed cutting.

Three protective windows shield the core focusing optics from spatter and dust, improving durability in daily production.

A compliant sensor mount uses shear screws (designed to break safely on impact) to protect the head and simultaneously send a collision stop signal to the controller.

Collision detection ties into the control system to cut power immediately after impact, preventing further damage.