4kW Laser Scanner Cutting Head

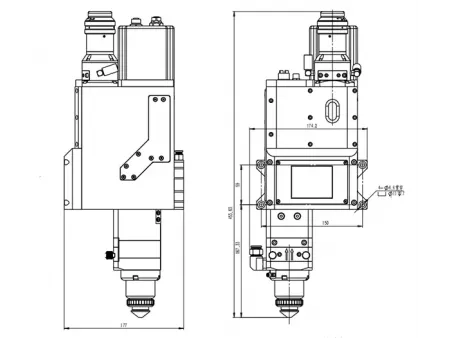

LDC40

Auto focus laser cutting head for processing highly reflective metals with power ratings of up to 4kW

LDC40

Auto focus laser cutting head for processing highly reflective metals with power ratings of up to 4kW

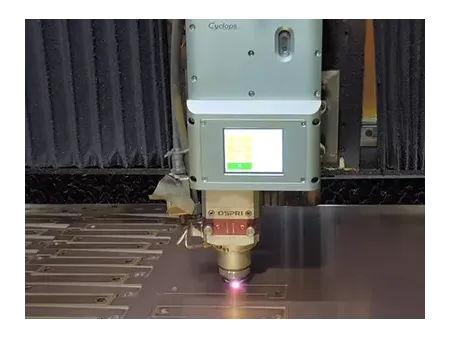

We supply 4 kW auto-focus laser scanner cutting heads suitable for reflective metals such as copper, brass, aluminum, and polished stainless steel. A galvo scanner places the beam quickly and precisely, while auto-focus keeps it on target as thickness or finish changes, so the kerf stays clean and the heat-affected zone small. Typical metal parts that can be cut with these laser cutting heads include battery tabs and busbars, enclosure panels, lighting reflectors, and decorative plates.

| Type | Auto Focus Fiber Laser Scanner Cutting Head |

| Model | LDC40 |

| Interface Type | QBH |

| Wavelength | 1080±10nm |

| Rated Power | 4kW |

| Focal Length | 150mm/200mm |

| Collimation Length | 100mm |

| Nozzle | FC-02 |

| Focusing Range | -15mm~ 15mm / -30mm~ 30mm |

| Centering Adjustment Range | ±1.5mm |

| Focusing Speed | 100mm/s |

| Auxiliary Gas Pressure | ≤2.5MPa |

| Wobble Range | 0-3mm |

| Wobble Speed | <4000mm/s |

| Weight | 9.4kg |

Our auto-focus laser scanner cutting heads are used in sheet-metal fabrication for highly reflective metals, brass, pure copper (red copper), and aluminum.

- Cutting pure-copper sheets

Eight preset scan patterns (e.g., line, arc, circle, spiral, raster) you can select on the controller. Pick the path that matches the geometry and hit your target speed with less trial-and-error.

A protective-window monitor tracks contamination. It prompts a timely swap; if levels cross the limit, the system triggers a safe stop to prevent poor cuts and protect the head.

Cooling across the housing, and the scanner block, keeps temperature steady during long shifts, helping focus stay put and edge quality remain consistent.

The protective window sits in a drawer type module, so you can pull it, replace it, and resume in minutes. Less downtime, more efficiency.

An optimized optical path improves energy coupling on brass, copper, and aluminum. You get higher speeds and greater workable thickness at the same 4 kW, with a clean kerf and a small HAZ.