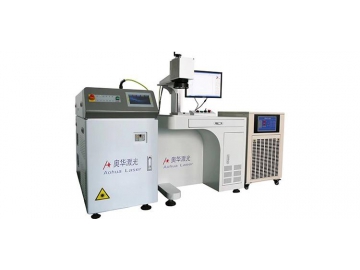

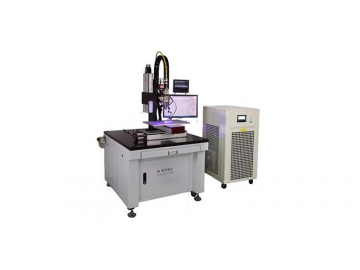

AW Series Fiber Laser Welding Machine AHL-AW200F/AW400F/AW600F

Applications:

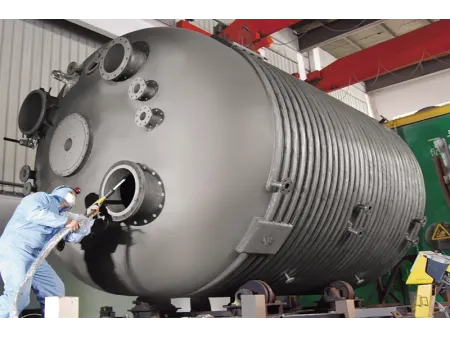

Mainly used for welding of same materials such as stainless steel, gold, silver, iron, aluminum, alloy, steel and diamond or welding of dissimilar materials. Widely used in sensors, mobile phone batteries, high-end bathroom products, medical equipment, craft gifts, watches, electronic components, precision machinery, electronic communications and other industries.

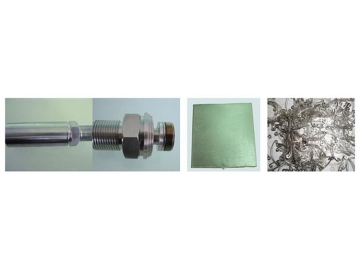

Sample pictures:

| Model | | | |

| Max. laser power | 200W | 400W | 600W |

| Laser wavelength | 1064nm | 1064nm | 1064nm |

| Max. energy per pulse | 90J | 110J | 130J |

| Laser welding depth | 0.1-1.5mm | 0.1-2.0mm | 0.1-3.0mm |

| Pulse width | 0.3-20ms | 0.3-20ms | 0.3-20ms |

| Continuous welding frequency | 1-100HZ | 1-100HZ | 1-100HZ |

| Adjustable facula size | 0.2-2mm | 0.2-2mm | 0.2-2mm |

| Repetition accuracy | ±0.01mm | ±0.01mm | ±0.01mm |

| Power consumption | ≤9KW | ≤12KW | ≤13KW |

| Electrical connection | 220V±10%/50HZ/40A | 380V±10%/50HZ/40A | 380V±10%/50HZ/40A |

| Control system | PC(CNC2000) | PC(CNC2000) | PC(CNC2000) |

| Positioning | Red indicator | Red indicator | Red indicator |

| Worktable stroke | 200mm*200mm | 200mm*200mm | 200mm*200mm |

Product advantages:

1. The laser welding machine can be programmed by computer to perform automatic or semi-automatic spot welding, butt welding, stitch welding, seal welding, and the welding of complex plane lines, arcs, and arbitrary trajectories.

2. After the optical fiber transmission welding, the welding quality is high, flat without air hole; The welding frequency can be used up to 50-100Hz, line speed up to 18mm/s, greatly improving the welding efficiency and quality.

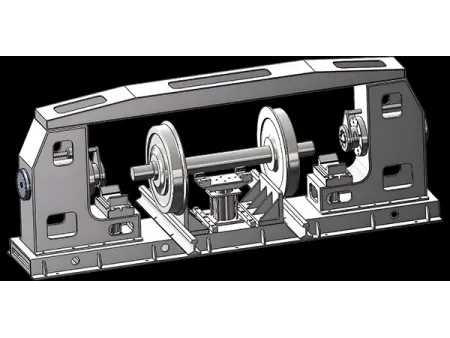

3. Equipped with four-dimensional ball screw table, imported servo control system and (optional) rotary table, can weld cylindrical objects and various shapes of objects.

4. The toughness of the material after welding is at least equivalent to the parent material.

5. Adjustable current waveform: Different waveforms can be set according to different welding consumables to match the welding parameters and welding requirements so as to achieve the best welding effect.