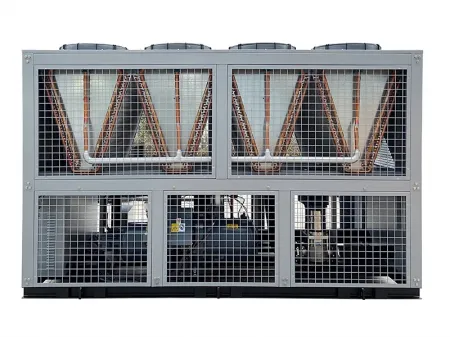

Air-Cooled Screw Chiller

Request a Quote

Industrial chiller with semi-hermetic screw compressor

- Cooling capacity: 30 ton to 600 ton

- Refrigerant: R22/R407C

- Power source: 3Ph 380V~415V 50Hz/60Hz

- Compressor: semi-hermetic screw compressor (brand options: Bitzer, Hanbell, Refcomp, etc.)

- Control system: PLC touch screen

- Chilled water temperature range: 5°C to 35°C

- Temperature control accuracy: ±1°C to 2°C

- Ambient temperature: -35°C to 40°C

- Min. dimensions (L×W×H): 2530×1700×1960mm

Features

- No cooling water circuit is required, and no cooling tower, pumps, or water treatment equipment are required. This reduces installation space and costs, making it suitable for areas with limited or poor water quality. Its modular structure enables it to be delivered as a complete unit, with on-site installation requiring only power and chilled water connections, reducing commissioning time by over 50%.

- The air-cooled screw chiller is designed to operate reliably in ambient temperatures between -10 °C and 35 °C. For specialized applications, it can be configured for low-temperature environments down to -35 °C or for high-temperature conditions up to 55 °C.

- Equipped with a third-generation industrial twin screw compressor featuring a 5:6 rotor profile. Capacity can be adjusted from 0% to 100%, either in stages or steplessly, reducing power consumption. Multi-unit intelligent control rotates operation between units according to load demand, extending service life.

- With no cooling water system, there’s no need to deal with scale or algae, lowering annual maintenance costs by about 40%. The screw compressor is designed for up to 100,000 hours of operation, while self-lubricating fan bearings extend maintenance intervals to 8,000 hours.

- Supports refrigerants such as R407C, R134A, and R513A. Noise reduction measures include low-speed fans, silencing fins, and insulated covers.

Typical Applications

- In city centers, especially where rooftop space is limited, air-cooled screw chillers are ideal for medium-sized offices, hotels, or shopping malls. In hospitals, laboratories, and schools, they also avoid the fogging and hygiene issues associated with cooling towers.

- In manufacturing, they can maintain stable injection mold temperatures (approximately ±1°C) or ensure printing presses operate normally without causing problems due to high temperatures. Food processors often use them to pre-cool storage rooms to 5-10°C or maintain low temperatures in meat production lines, all without the risk of water contamination associated with traditional systems.

- Small data centers and 5G base stations often choose these types of screw chillers because they are easy to maintain and can be deployed in a decentralized manner. They are also a good backup option for sites that rely on water-cooled chillers, allowing them to step in if water supply problems cause servers to overheat.

- Industrial parks and logistics centers use distributed air-cooled screw chillers to meet fluctuating cooling needs. For temporary events such as trade shows or sporting events, these units can be quickly installed and removed without the need for extensive infrastructure construction.

- In water-scarce regions, such as the Middle East or parts of Africa, air-cooled screw chillers can provide stable cooling year-round without consuming precious water resources.

Technical Specifications

| Model(HTS-***) | | | | | | | | | | | | | | | | 200AD | | | | | |||

| Nominal cooling capacity | 7℃ | kcal/h | 89870 | 118078 | 126850 | 169764 | 200122 | 215860 | 235554 | 275716 | 336260 | 350192 | 179740 | 236156 | 253700 | 339528 | 400244 | 431720 | 471108 | 551432 | 672520 | 700384 | |

| kW | 104.5 | 137.3 | 147.5 | 197.4 | 232.7 | 257 | 273.9 | 320.6 | 391 | 407.2 | 209 | 274.6 | 295 | 394.8 | 465.4 | 502 | 547.8 | 641.2 | 782 | 814.4 | |||

| 12℃ | kcal/h | 108360 | 142330 | 152822 | 204508 | 241144 | 239720 | 283714 | 332132 | 404200 | 421830 | 216720 | 284660 | 305644 | 409016 | 482288 | 519440 | 567428 | 664264 | 808400 | 843660 | ||

| kW | 126 | 165.5 | 177.7 | 237.8 | 280.4 | 302 | 329.9 | 386.2 | 470 | 490.5 | 257 | 331 | 355.4 | 475.6 | 560.8 | 604 | 659.8 | 772.4 | 940 | 981 | |||

| Input power | kW | 38.7 | 47.6 | 53.3 | 69.8 | 78.3 | 83.7 | 90.6 | 109.4 | 129.8 | 133 | 76.6 | 95.2 | 106.6 | 137.6 | 156.6 | 167.4 | 181.2 | 218.8 | 259 | 266 | ||

| Power source | 3PH 380~415V 50HZ/60HZ | ||||||||||||||||||||||

| Refrigerant | Type | R22/R407C | |||||||||||||||||||||

| Charge | kg | 28 | 35 | 42 | 52 | 60 | 65 | 70 | 84 | 98 | 105 | 28×2 | 35×2 | 42x2 | 52×2 | 60x2 | 65×2 | 70×2 | 84×2 | 98×2 | 105x2 | ||

| Control | Thermostatic expansion valve | ||||||||||||||||||||||

| Compressor | Type | Semi-hermetic screw compressor | |||||||||||||||||||||

| Power | kW | 35.1 | 44 | 48.5 | 63.4 | 71.9 | 76.5 | 83.4 | 99.8 | 119 | 122.2 | 35.7*2 | 44*2 | 48.5*2 | 63.4*2 | 71.9*2 | 76.5*2 | 83.4*2 | 99.8*2 | 119*2 | 122.2*2 | ||

| Start mode | Y-△ | ||||||||||||||||||||||

| Capacity control | % | 0-25-50-75-100 | |||||||||||||||||||||

| Evaporator | Type | Shell and tube evaporator / SS plate heat exchanger | |||||||||||||||||||||

| Chilled water volume (7℃) | m³/h | 18 | 23.6 | 25.7 | 34.4 | 40.5 | 43.1 | 46.4 | 55 | 67.3 | 69.5 | 35.6 | 46.5 | 50.8 | 68 | 80 | 86.3 | 92.8 | 110.6 | 134.5 | 139 | ||

| Water pressure drop | kPa | 32 | 35 | 38 | 42 | 45 | 42 | 43 | 43 | 41 | 41 | 45 | 43 | 43 | 41 | 42 | 45 | 45 | 42 | 46 | 46 | ||

| Pipe connection | inch | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 5 | 5 | 3 | 4 | 4 | 5 | 6 | 6 | 6 | 6 | 8 | 8 | ||

| Condenser | Type | Air cooled type high efficiency finned copper tube | |||||||||||||||||||||

| Fan | Type | High-flow low-noise axial fan | |||||||||||||||||||||

| Power | kW | 0.6*6 | 0.6*6 | 0.8*6 | 0.8*8 | 0.8*8 | 0.9*8 | 0.9*8 | 0.9*8 | 0.9*12 | 0.9*12 | 0.8*8 | 0.9*8 | 0.8*12 | 0.9*12 | 0.8*16 | 0.9*16 | 0.9*16 | 0.8*24 | 0.9*24 | 0.9*24 | ||

| Air volume | m³/h | 53520 | 53520 | 74520 | 99360 | 99360 | 120960 | 120960 | 149040 | 181440 | 181440 | 99360 | 120960 | 149040 | 181440 | 198720 | 241920 | 241920 | 298080 | 362880 | 362880 | ||

| Safety devices | Compressor internal protection | ||||||||||||||||||||||

| Overcurrent protection | |||||||||||||||||||||||

| High/low pressure protection | |||||||||||||||||||||||

| Over temperature protection | |||||||||||||||||||||||

| Flow protection | |||||||||||||||||||||||

| Phase sequence/phase loss protection | |||||||||||||||||||||||

| Low coolant level protection | |||||||||||||||||||||||

| Anti-freeze protection | |||||||||||||||||||||||

| Discharge overheat protection | |||||||||||||||||||||||

| Dimensions | Length | mm | 2530 | 2650 | 2950 | 3310 | 4000 | 4300 | 4300 | 5650 | 5980 | 5980 | 4000 | 4300 | 5650 | 5980 | 8000 | 8600 | 8600 | 11300 | 11960 | 11960 | |

| Width | mm | 1700 | 1800 | 1800 | 1800 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 1800 | 2000 | 2000 | 2000 | 1800 | 2000 | 2000 | 2000 | 2000 | 2000 | ||

| Height | mm | 1960 | 2060 | 2160 | 2200 | 2050 | 2170 | 2170 | 2070 | 2170 | 2170 | 2050 | 2170 | 2070 | 2170 | 2050 | 2170 | 2170 | 2070 | 2170 | 2170 | ||

| Net weight | kg | 1300 | 1600 | 1900 | 2350 | 2550 | 2700 | 2800 | 2950 | 3100 | 3200 | 2500 | 2950 | 3350 | 4100 | 4350 | 4550 | 4750 | 5200 | 5500 | 5700 | ||

| Running weight | kg | 1450 | 1750 | 2100 | 2550 | 2800 | 2950 | 3050 | 3250 | 3400 | 3500 | 2800 | 3250 | 3750 | 4500 | 4850 | 5050 | 5250 | 5800 | 6100 | 6300 | ||

The above specifications are based on the following design conditions:

- Chilled water inlet/outlet temperature: 12 °C / 7 °C

- Cooling air inlet/outlet temperature: 35 °C / 43 °C

Models larger than HTS-150AD adopt a modular design.

Note: The cooling capacity of units using R407C will be approximately 5% lower than those using R22. Optional refrigerants: R407C / R134a.

We reserve the right to modify the specifications without further notice

Tell us about your project

We customize and deliver industrial chillers and process cooling equipment to match your specifications