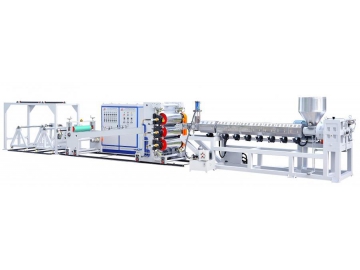

Corrugated Roofing Sheet Extrusion Line

Corrugated Roofing Sheet Making Machine, Production Line for Corrugated Sheet, Roofing Sheet Production Line

-

Corrugated tile production line

-

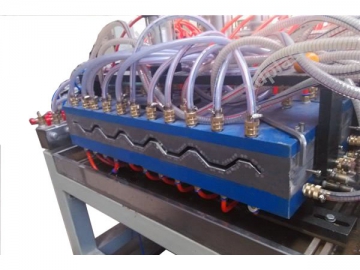

Molds for corrugated tiles

-

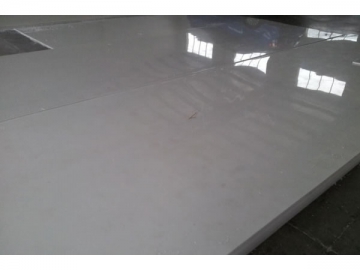

Corrugated tiles

-

Applications of corrugated tiles

PVC corrugated roofing sheet extrusion line is comprised of conical twin screw extruder, molds, vacuum sizing system, traction machine, and cutting machine, among which the extrusion molds are designed with co-extrusion techniques and multi cavities. Vacuum sizing device and specially-designed cooling channels are employed for the forming molds for better forming. This PVC extrusion line is suitable for making PVC corrugated sheets.

Composite corrugated tiles are structured basing on PVC, and co-extruded with some weather-resistance plastic resin like acrylic plastics. There is no asbestos contained in the tiles.

Allowable width of corrugated tiles: 600-2000mm;

Allowable thickness: 1-4mm

Advantages & Applications of PVC Corrugated Tiles

1. PVC corrugated tiles are of large strength, high impact resistance and long service life. They are good choice for decoration and are easy to be constructed.

2. PVC composite tiles are mainly applied in buildings with high decoration requirements, like parks, and public galleries. They are a perfect replacement for asbestos tiles and glass steel tiles.

3. It is a kind of tiles applicable in mono-pitched roof houses whose base is cast-in-place concrete slab, and other houses with slope roofs.

4. Composite corrugated tiles show higher weather resistance, and longer life comparing with common plastic tiles.

5. PVC tiles are suitable for houses with a roof slope of 1: 3 (18.5°) ~1: 0.58 (60°).

6. This kind of tiles can be used for house roof with waterproof level of Ⅱ(1-2 waterproofing sets, with cushion included), Ⅲ (1 waterproofing set, with cushion included),and Ⅳ (1 waterproofing set, without cushion), as well as a waterproof layer of roof with Ⅰ(2 waterproofing set, with cushion included). It is not suggested to take waterproof coating as a measure for waterproofing.

| Equipment | Quantity | |

| 1 | Screw feeder | 1 |

| 2 | SJZ80/156 or 92/188 conical twin screw extruder | 1 |

| 3 | SJ50/30 single screw extruder | 1 |

| 4 | Dryer and feeding machine | 1 |

| 5 | Molds and distributor | 1 |

| 6 | Forming equipment (forming mold, traction machine, cutting machine, and stacker) | 1 |