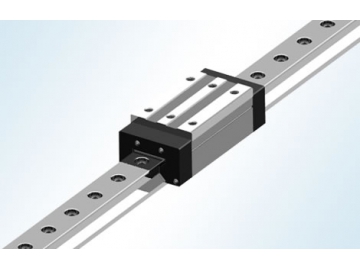

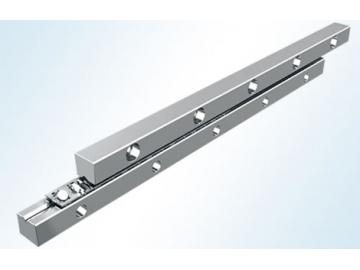

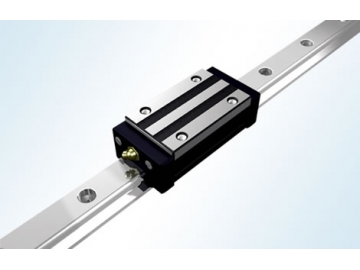

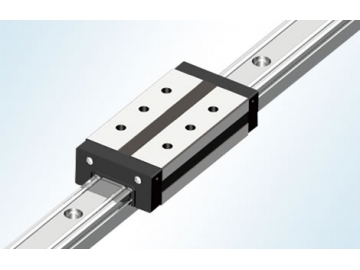

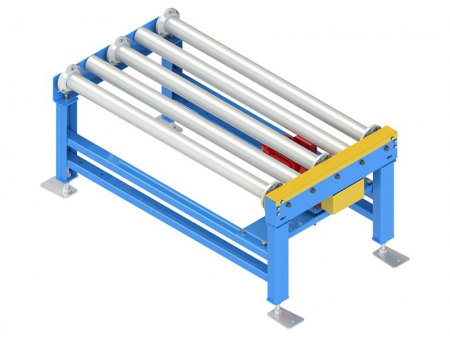

Roller Guide Block

The roller guide block consists of a slide block, roller and reverse unit. Rollers move circularly in the block which has been precisely tempered and ground. To prevent rollers running out from the block, the rollers are designed as step rollers and the block is designed with special slot. This gives the roller a self centering function and avoids side moving. The roller has good performance in guiding, and allows high positioning accuracy. As a result, our roller guide blocks have found a wide variety of applications in many fields. A smaller one is available for linear motion parts of mold and instrument. A larger guide block could be used for plane linear motion of heavy machine tools and precise instrument, especially NC, CNC machine tools.

Our roller guide block is a precision linear motion element, providing high load carrying capacity and rigidity. It achieves high sensitivity and highly functional plane linear motion. In the condition of heavy load and varied load, the roller guide block has small elastic deformation and can get stable linear motion without crawl. Our roller guide block is flexible to use, and is not restricted by the length of machine tools. The quantity of blocks needed depends on loading capacity and specification.

Accuracy of the Roller Guide Block

The accuracy of the roller guide block mainly relies on the height of guide block. If several roller guide blocks are used in the same plane, they must have consistent height to get equal and balanced load. Usually, height deviation is less than 10μm.

Unit: μm

| Accuracy Class | Allowed Tolerance of Height | Height Variation of the Same Group |

| 2 | 0-10 | 2 |

| 3 | 3 | |

| 4 | 5 | |

| 5 | 10 |

Unit: μm

| Accuracy Class | 2 | 3 | 4 | 5 | ||||

| Grade Code | Height Difference | Grade Code | Height Difference | Grade Code | Height Difference | Grade Code | Height Difference | |

| Accuracy | B2 | 0~-2 | C3 | 0~-3 | D5 | 0~-5 | 0~-10 | |

| B4 | -2~-4 | C6 | -3~-6 | D10 | -5~-10 | |||

| B6 | -4~-6 | C9 | -6~-9 | |||||

| B8 | -6~-8 | |||||||

| B10 | -8~-10 | |||||||

NOTE

1. Height variation of the same group is the difference of max. and min. height (H) of the roller guide blocks used in the same plane.

2. Please show the number of roller guide blocks used in the same plane when ordering.

3. Our company will produce in grade according to the accuracy class. Except accuracy class 5, other classes are coded according to the height dimensions, and the same codes are in the same group during installation. The customer only needs to specify the accuracy class in ordering, not the grade code.

Rated Load and Life of Roller Guide Block

Basic rated dynamic load C

The basic rated dynamic load is, i.e., a group of same roller guide blocks runs separately and 90% of them reach rated life 100km in the condition of no damage of material due to contact fatigue, a constant load in the same direction and quantity.

Basic rated static load C0

The basic rated static load defines static load. The nominated contact stress constant reaches max. load in the center of the contact area between rollers and guide.

Life Calculation

1) Calculation formula of roller guide block life

L---rated life(km) C---rated dynamic load(KN) PC---calculated load(KN) ft---temperature coefficient fc---contact coefficient fa---accuracy coefficient fw---load coefficient fh----hardness coefficient(actual hardness of groove HRC/58)3.6

2) Calculation of life time

Lh-----life time(h) l-----stroke length(mm) n----repetitive times per min(min-1) L----rated life(km)

- GZD

- ①

- 15

- ②

- x

- 53

- ③

- 一

- Ⅱ

- ④

- 一

- 3

- ⑤

- 一

- C6

- ⑥

- ① Code of roller guide block

- ② Nominal dimension of guide block

- ③ Length of guide block

- ④ Number of guide block used in the same plane

- ⑤ Accuracy grade

- ⑥ Grade code

Unit: mm

| Model | Length L | Width W | Height H | Dia. for Mounting Hole d×D×h | Center Distance of Mounting Hole | Basic Rated Dynamic Load C(KN) | Basic Rated Dynamic Load C0(KN) | Weight Block per/pc | |

| A | B | ||||||||

| GZD15 ×53 | 52.8 | 26.5 | 15 | Φ3.4 | 19 | 19.3 | 23.0 | 29.0 | 0.12 |

| GZD20 ×70 | 70 | 30 | 20 | Φ3.6 ×Φ6 ×4 | 26 | 23 | 38.3 | 53.4 | 0.25 |

| GZD30 ×123 | 123 | 40 | 30 | Φ4.5 ×Φ8.5 ×5 | 58 | 30 | 63.5 | 72.3 | 0.92 |

| GZD40 ×132 | 132 | 51.4 | 40 | Φ5.5 ×Φ10 ×6 | 50.8 | 41.5 | 89.1 | 121 | 1.7 |

Installation and Operation of the Roller Guide Block

To guarantee the assembly accuracy and parallelism between the block and rails, proper installation instructions should be followed. For details, please refer to following table. To achieve the best performance, the bed rail should be hardened to face more than HRC58, surface roughness over Ra0.4 to 0.8μm, and hardened depth should reach 1 to 2mm.

| Item No. | Method of Installation | Sketch | Features |

| 1 | Directly installed | Simple structure, but with higher producing accuracy requirements to the parts | |

| 2 | Installed in the pad board | Precision controlled by grinding the plate | |

| 3 | Installed in the wedge iron | Easy to adjust | |

| 4 | Installed in the adjustable gasket | Need not precision machining to the mount surface, but it takes more time to adjust the accuracy | |

| 5 | Installed in the spring pad | Because of the automatic compensation of the spring, this method requires less to the parts, but you should mind the preload of the spring |

To make the roller guide block achieve the expectant performance and durability, it should ensure the following installation and accuracy.

1. The parallelism between the mounting face and guide face: To make the guide block bears force equally, the parallelism tolerance between the roller block mount ref. side and guide rolling contact surface should be less than 0.02mm/1000mm.

2. Lean accuracy in length direction of roller: To prevent the roller from moving sideway or skidding, the parallelism of roller length direction and mounting ref. side of machine tool should be less than 0.02mm/300mm.

3. Lean accuracy of roller block side face: To avoid the roller moving sideway or skidding, the parallelism of roller axes direction and right and left of rolling face should be less than 0.02mm/300mm.

Lubrication of the Roller Guide Block

Lubrication is used to reduce friction and avoid overheating. It protects the inner structure and ensures the function of the roller guide block. If the roller cross guide moves at a high speed (V>=15m/min), N32 lubrication oil is recommended (refer to GB443-84), whose viscosity is 28.5~35.2 cst when temperature is 40ºC. The roller guide block should be lubricated periodically or connected with an oil hose for forced lubrication. Lithium grease (GB7324-94 2#) is recommended, if roller cross guide is running at low speed (V<=15m/min).

As a China-based roller guide block manufacturer and supplier, YiGong also offers ball linear motion guide, heavy duty ball screw, concave linear motion spline, and much more.