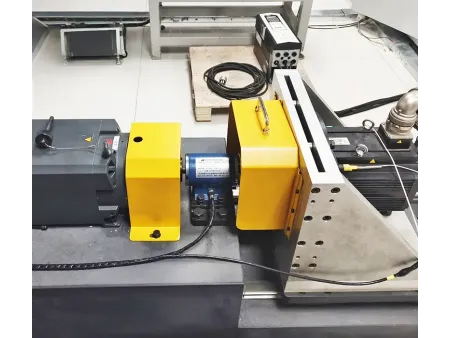

Electric Motor Test Bench

Electric motor testing system used to perform load tests of the motor

The electric motor test bench is a specialized platform combining a motor load system with a controlled environment chamber. This configuration enables long-duration testing under stable temperature and humidity, recreating real-world conditions to assess motor durability and reliability.

This type of testing system is mainly used to measure performance indicators such as output power, torque, rotational speed, efficiency, and temperature rise when the motor operates under different load scenarios. By simulating diverse operating conditions, it helps engineers verify that each motor performs to design specifications and can withstand demanding use. Comprehensive test data gathered on the bench supports product development, quality assurance, and performance optimization, ensuring motors deliver consistent results in applications like industrial automation, electric vehicles, and specialized equipment.

The electric motor test bench is suitable for a wide range of industries where motors play a central role. It is widely used in fields such as industrial automation, new energy vehicles, aerospace, and home appliances. In these sectors, motors serve as essential power sources, and there are strict requirements for their performance, reliability, and energy efficiency. This testing system helps manufacturers validate that motors consistently meet these demanding standards before products reach the market.

- The test bench delivers precise and adjustable load simulation from no load to overload, with accuracy within ±0.5%, so performance tests closely match real application scenarios.

- It supports comprehensive measurement of parameters such as input power, output power, torque, speed, efficiency, and power factor, providing a detailed view of motor performance.

- Equipped with high-precision sensors and advanced instruments that ensure data accuracy and reliability during each test session.

- The flexible configuration can adapt to different motor types and power ranges, while automation functions allow automatic loading, measurement, data acquisition, and analysis to improve testing efficiency.