Laser Welding Heads for Lithium Battery

Laser processing heads for battery production

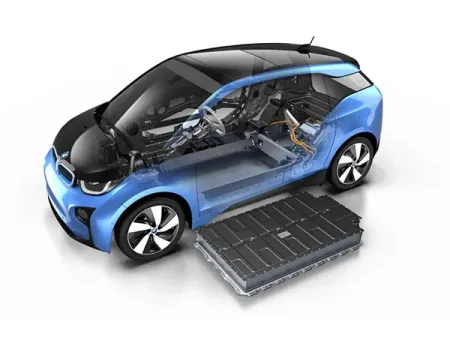

Building lithium batteries for new energy vehicles requires over 20 precise welding steps, from securing conductive pathways to ensuring airtight seals, each one pushing the boundaries of precision manufacturing. The quality of each weld directly impacts the safety, durability, and overall performance of the entire vehicle.

Welding in lithium battery production demands absolute precision, small yet strong weld spots, excellent conductivity, and minimal thermal damage. Our laser welding heads are engineered to meet these exacting requirements. With outstanding focusing performance and wobble welding capabilities, they ensure stable, high-consistency welding for applications such as electrode tab joining, cell sealing, and cover plate welding. Capable of reliably handling copper-to-aluminum dissimilar metal welding with minimal heat-affected zones, these welding heads are widely applied in power battery manufacturing, energy storage systems, and other intelligent production lines. They provide the high efficiency, precision, and consistency that the new energy industry depends on for next-generation battery technologies.