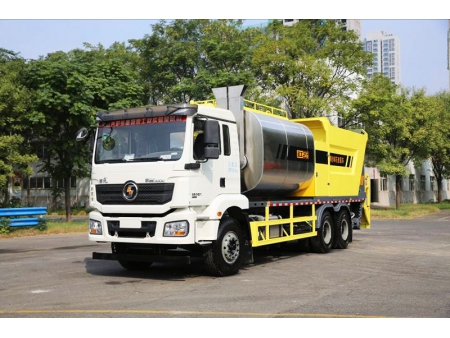

Chip Spreader / Chip Sealing Distributor, 0810B

Road construction equipment for synchronous spreading of asphalt and stone chips

The chip spreader/chip sealing distributor is designed to provide simultaneous distribution of asphalt and stone chips for improved quality of pavement seal layers. It is ideal for the construction of bottom seal layers and upper seal layers of highways and bridges, as well as for the layering construction of asphalt pavement, and separate application of asphalt and macadam in special conditions. Additionally, it is suitable for interlayer treatments and reconstruction of high-grade highways, as well as the construction of rural roads with low traffic volume.

This synchronous asphalt chip sealing distributor is equipped with a Belgium JOHNSON asphalt pump for superior self-priming capabilities, extensive variable speed range, and optimally sealed deliverance of asphalt for consistently superior results.

This chip spreader/chip sealing distributor is equipped with a powerful spiral mixing system, which helps maintain an even temperature in the asphalt tank, thus improving heating efficiency. Furthermore, it prevents rubber powder asphalt from separating, precipitation of emulsified asphalt, and demulsification. It even has a high-viscosity spray capability for rubber asphalt.

| Model | HGY5255TFCS6 |

| Chassis Model | SX1259MC4C1 |

| Chassis Manufacturer | Shacman (Optional upon request) |

| Chassis Series | Delong new M3000 |

| Chassis Engine Power | 257 (350) kW (hp) |

| Wheel Base | 4975 1400 mm |

| Emission Standard | Euro 6 (Optional upon request) |

| Asphalt Tank Volume | 8500 L |

| Material Tank Volume | 10000 L |

| Synchronous Seal Layer Width | 4200 mm |

| Asphalt Spray Volume | 0.2-3 kg/㎡ |

| Stone Chip Spray Volume | 2-22 L/㎡ |

| Asphalt Spray Precision | 1% |

| Stone Chip Diameter | 3-30 mm |

| Spray Medium | Rubber asphalt, modified asphalt, hot asphalt, and emulsified asphalt |

| Asphalt Heating Method | Thermal oil heating (with automatic temperature control) |

| Asphalt Heating Rate | 20 ℃/h |

| Recommended Construction Speed | 3-6 km/h |

| Maximum Speed | 89 km/h |

| Total Weight | 25000 kg |

| Dimension (L×W×H) | 10700×2550×3800 mm |

-

The Shacman Delong M3000 chassis is selected for this heavy truck, boasting a 350 horsepower engine, meeting China VI emission standards, and providing a strong bearing capacity. The high configuration cab enables more comfortable driving, while the gear features a high and low-speed conversion and a fast reverse gear, in turn improving working efficiency.

-

The spray bar has been uniquely designed to prevent collisions and obstacles, ensuring its protection from any damage.

-

The cab contains all the necessary equipment for a single person to operate the construction process easily and effectively.

-

This special controller, which is mounted onto the vehicle, is designed to automate the sealer/distributor’s operation and provide accurate pump speed measurement via an encoder, thus ensuring precise control of the spraying amounts during the construction process.

-

The tank is designed with two imported diesel burners that deliver high-efficiency combustion and heat quickly. An automated ignition and temperature control system also enensuresafety and stability throughout the heating process.

- The hydraulic system of the main vehicle utilizes the full-power take-off mode to provide stability, efficiency, and eco-friendly performance.

- The width of the stone chip and asphalt spreading can be controlled independently through multiple cylinders. Each cylinder can be individually adjusted and manipulated for desired results.

- The stone chip tank is equipped with a high-definition camera capable of monitoring the level of stone material at any given time.

- The operating system is designed with both manual and automatic systems to guarantee the continual operation of the equipment. By having these two independent systems, any downtime can be prevented and the machine can be ready to use at any time.