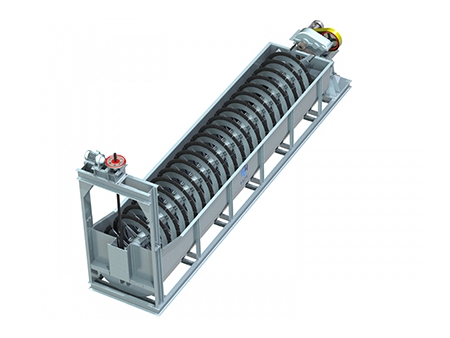

Spiral Classifier

Working Principle

Mineral slurry enters the pool from sedimentation area via the discharge outlet. The pool is designed tilted, right above the sedimentation area. When the rotor is at low speed, it mixes the slurry, allowing particles to float on the surface and overflow through the outlet. The coarse particles sank to the bottom, transferred by spirals and discharged as coarse materials.

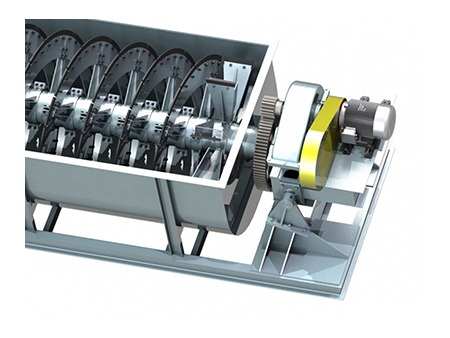

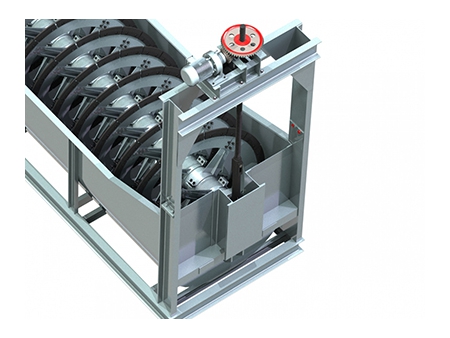

- The spiral near the downflow weir completely sanks below the slurry in the sedimentation area which is deep with large space.

- A lifting device is added to the sand-returning end so that the big spoon for scooping coarse particles is not needed.

- Saves 1-1.5 kWh per ton.

- No recondition of the big spoon is neede.

- Cushion the imbalanced impact force to the big and small gears.

Suitable to classify slurry according to the particle size.

Classifier is one of the most frequently used devices in mining, used widely in mineral processing plants, construction materials, silicate and chemical industry. In small, medium and large scale plants, the classifier is used to classify mineral ores, such as gold, silver, bronze, lead, zinc, nickel, manganese, iron and so on, stones such as rock, granite, barite, quartz, graphite, feldspar and fluorite.

| Model | Spiral Speed (r.p.m) | Processing Capacity (t/d) | Spiral Diameter (mm) | Spiral Length (mm) | Slope of Water Tank (°) | Motor Power (kW) |

FG(T)-300 | 7.7 | 10-30 | 300 | 3900 | 14-18.5 | 2.2 |

FG(T)-500 | 8 | 21-75 | 500 | 4390 | ||

FG(T)-750 | 7.8 | 31-165 | 750 | 5500 | 3 | |

FG(T)-1000 | 6.7 | 85 | 1000 | 6500 | 5.5 | |

FG(T)-1200 | 5,6,7 | 150 | 1200 | 6500 | 5.5 | |

FG(T)-1500 | 2.5,4,6 | 235 | 1500 | 8265 | 7.5 | |

FG(T)-2000 | 3.5,5.5 | 400 | 2000 | 8400 | 11;15 | |

FG(T)-2400 | 3.6 | 580 | 2400 | 9130 | 15 | |

FG(T)-3000 | 3.2 | 890 | 3000 | 12500 | 22 |

| Model | Spiral Speed (r.p.m) | Processing Capacity (t/d) | Spiral Diameter (mm) | Spiral Length (mm) | Slope of Water Tank (°) | Motor Power (kW) |

2FG-1200 | 5,6,7 | 310 | 1200 | 6500 | 14-18.5 | 5.5×2 |

2FG-1500 | 2.5,4,6 | 460 | 1500 | 8265 | 7.5×2 | |

2FG-2000 | 3.6,5.5 | 750 | 2000 | 8400 | 15×2 | |

2FG-2400 | 3.63 | 1160 | 2400 | 9130 | 22×2 | |

2FG-3000 | 3.2 | 1785 | 3000 | 12500 | 30×2 |