Drip Coffee Packaging Machine (Advanced Type)

Request a Quote

LQ-DC-2

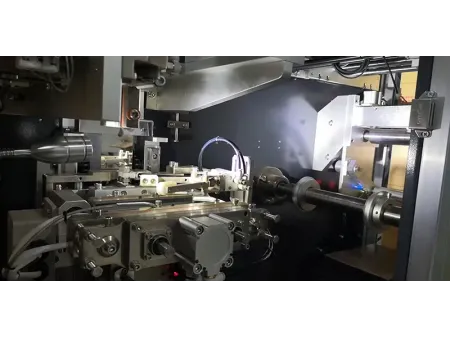

Ultrasonic sealing and packaging machine for packaging drip bag coffee

Our latest drip coffee bag packing solution is designed to pack various types of drip coffee bags, including standard, non-woven, and VFR. This packaging system uses fully ultrasonic sealing for the inner bags, offering superior packaging performance compared to traditional heat-sealing methods. The specialized slide doser weighing system minimizes coffee powder waste, ensuring both efficiency and accuracy.

Main Components

Specifications

| Working Speed | Approximately 50 bags/min |

| Bag Size | Inner bag: L90mm×W70mm Outer bag: L120mm×W100mm |

| Sealing Method | Fully 3-side ultrasonic sealing 3-side heating sealing |

| Weighing System | Slide doser |

| Weighing Range | 8-12grams/bag (based on the material’s proportion) |

| Filling Accuracy | ±0.2 grams/bag (depending on the coffee material) |

| Air Consumption | ≥0.6MPa, 0.4 m³/min |

| Power | 220V, 50Hz, 1Ph |

| Weight | 680kg |

| Overall Dimensions | 1400mm×1060mm×2691mm |

Main differences from standard model

- The program has been optimized for better overall performance.

- The bag former is updated with a Teflon coating on the inner bag former to prevent coffee powder from sticking, ensuring accurate weight.

- An additional lamp has been installed for the outer bag device.

- A vibrating device has been added for feeding and the inner bag former, ensuring smooth coffee powder flow and preventing sticking.

- Additional nitrogen gas tubes have been incorporated for the inner bag forming section to maintain coffee freshness for a longer period.

- The outer bag film device has been slightly modified for improved functionality.

Features

- The working efficiency is higher than conventional models available in the market

- The three-side ultrasonic sealing device for the inner bag ensures excellent packaging performance

- High accuracy with a margin of ±0.2 grams per bag

- An automatic air pressure detection device ensures reliable operation

- Equipped with a multifunctional sensor system that includes alarms for no coffee material, no packing material, eye-mark detection, empty inner bag, inner bag connection, and outer envelope eye-mark

- Enhanced safety with a guard device