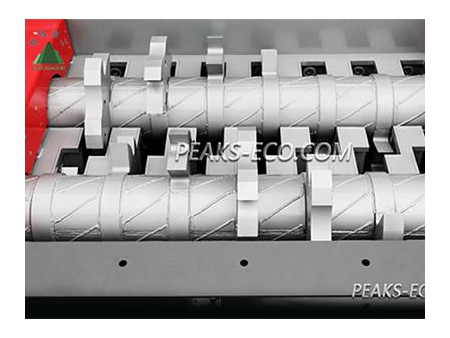

Double-Shaft Primary Shredder

Request a Quote

Double-shaft primary shredder is used for the size reduction of large materials and solid waste pre-shredding, with shearing, chopping, tearing, and pressing. Engineered to perform durability and minimize maintenance costs, our double-shaft primary shredders can easily handle complex mixed solid waste, unsorted household garbage, construction debris, or industrial waste. The shredders designed by our company boost operational efficiency and processing capabilities.

Technical Specifications

| Shredder table size | 4072×2300mm |

| Shredding area | 2420×2000mm |

| Number of shaft | 2 |

| Number of rotating cutters | 2×9pcs (welded on the shaft) |

| Cutter thickness | 80mm (Hardox 500) |

| Cutter teeth arrangement | One forward, two backward (Hardox 500) |

| Number of stationary cutters | 20pcs |

| Rotation speed | 16-41rpm |

| Speed control | Analogue speed control |

| Gap between stationary cutters | 160mm |

| Central lubrication | Standard configuration |

| Power | 2×132kW |

| Drive system | Dual hydrostatic drive |

| Oil cooling system | Air cooling (water cooling is optional) |

| Numerical control | Siemens S7 |

| Remote control | Communication protocol (wire or wireless control is optional) |

| Overload protection | Yes |

| Shredding routine procedure | 6 |

| Hour count | Yes |

| Color | Gray RAL 9002 |

| Iron gray RAL 7011 | |

| Particle size | 90% < 250mm (different material particle size measurement results can be provided) |

Equipment Configuration

- Rotating Blades: Featuring one forward-facing and two backward-facing knife teeth, these blades rotate closely around the fixed blades. A 160mm gap between each set of fixed blades on the shredding table allows sand, soil, gravel, and small metal fragments to pass through easily, significantly reducing wear on the shredding table. Depending on the type of waste, up to 90% of the crushed material achieves a particle size below 200mm.

- Central Lubrication System: Automatically manages lubrication of the main bearings to ensure smooth operation and extended component life.

- Power Units: Consists of a motor, hydraulic system, oil cooler, and PLC control unit. The shaft speed ranges from 16 to 41 rpm, with optional simulated shaft speed control available.

- Hydraulic System: Equipped with variable pumps featuring power control, integrated supply pumps, and hydraulic motors mounted on each shaft. This dual hydraulic system delivers maximum processing power and reliable performance.

Features

- Excellent shredding performance for all solid waste types

- High efficiency and good performance to meet different processing requirements

- High torque with low revolving speed and minimal fuel consumption

- The shredder’s cutting blades are produced using a special steel to extend their working lifetime and enhance performance

- Unique blades maximize the use of upstream sorting facilities

Custom options

- Size

- Motor configuration