Sheet to Sheet Litho Laminator with Stacker

Request a Quote

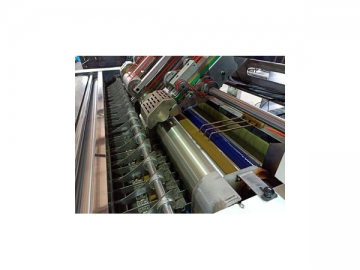

Sheet to sheet litho laminator with sheet stacker: This machine combines a sheet to sheet laminating(mounting) machinewith a sheet stacker, and that results in a high efficiency device.

According to the different width of the paper that can be processed, we produce two types of sheet to sheet laminating(mounting) machinefor you to choose from.

YB-1450HS Fully automatic sheet to sheet litho laminator with sheet stacker

| Max sheet size | 1450×1450mm |

| Min sheet size | 500×500mm (20''x20'') |

| Top sheet thickness | 150-500g |

| Bottom sheet thickness | A/C/C/E/F Corrugated paper, four ply corrugated paper |

| Fitting precision | ±1mm |

| Air consumption | 1.2m3/min |

| Measurement | 23.6*2.7*3M |

| Machine power | 30KW |

YB-1650HS Fully automatic sheet to sheet litho laminator with sheet stacker

| Max sheet size | 1650×1450mm |

| Min sheet size | 500×500mm(20''x20'') |

| Top sheet thickness | 150-500g |

| Bottom sheet thickness | A/C/C/E/F Corrugated paper, four layers corrugated paper |

| Fitting precision | ±1mm |

| Air consumption | 1.2m3/min |

| Measurement | 23.6*2.9*3M |

| Machine power | 32KW |

(The parameters of the fully automatic sheet to sheet laminating(mounting) machinewith paper converting machine can be changed according to the actual needs of the customers.)

Features

- The machine collects the paper instead of the manual delivery, and the paper is stacked in a front and back sides alternately placed stacking method, which meets the stacking requirements of the sheet to sheet laminating(mounting) machineand saves labor time.

- The sheet to sheet laminating(mounting) machineautomatically adjusts the various working steps according to the input paper size, which reduces the manual adjustment of the machine.

- The servo motor is positioned to compensate the position of the upper paper according to the position of the bottom paper, which makes the paper fit more precise.

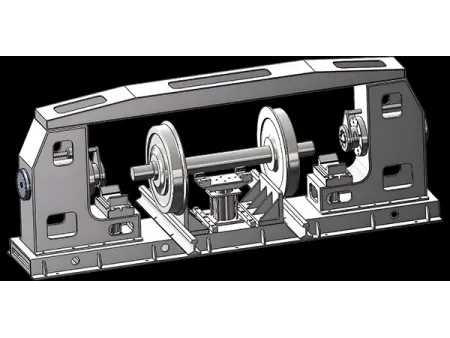

Components

- Bottom sheetsystem: The bottom sheet system uses suction to automatically feed paper. The bottom sheet system ensures that the corrugated paper and the cardboard can be smoothly discharged while the machine is running

- Feeding unit: The feeding unit enables the high speed and smoothness of paper feeding and improves the production efficiency of the sheet to sheet laminating(mounting) machineduring the operation process, regardless of thick paper or thin paper.

- Electrical system: The man-machine interface is combined with the PLC to display various information such as warnings and detection faults on the screen, making it easier for users to quickly know the condition of the machine

- Pre-loading unit: Under the condition of not stopping the machine, the pre-loading unit stack up the next stack of upper paper to improve the efficiency

- Gluing system: The gluing system uses a stainless steel gluing roller. The gluing roller made of stainless steel can be used for a long time to avoid rust and make the machine more durable.

- Transmission system: The transmission system makes the paper conveying smooth and fast during the operation of the laminating machine. The machine operates with low noise to provide a safer working space for the operator.

- Positioning system: The positioning system utilizes multiple sets of photoelectric to sense the relative position of the bottom paper. During the working process of the laminating machine, the positioning system makes the upper paper and the bottom sheet fit accurately.

- Flip flop system: The fitted paper is subjected to a positive and negative automatic stacking according to the set quantity.

Product package

Our fully automatic sheet to sheet litho laminator with sheet stacker is sold in Jordan, Finland and other countries. You can click on the picture of the machine used in our customer's factory to view it.

YB-1450HS Fully automatic sheet to sheet litho laminator with sheet stacker in Jordan

YB-1450HS Fully automatic sheet to sheet litho laminator with sheet stacker in Jordan YB-1650HS Fully automatic sheet to sheet litho laminator with sheet stacker in Finland

YB-1650HS Fully automatic sheet to sheet litho laminator with sheet stacker in Finland

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos