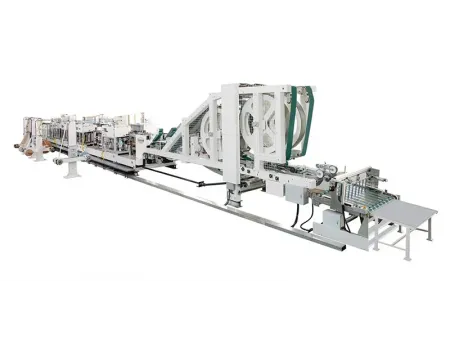

Valve Bag Bottomer Machine

Paper Sack Production

Multi-wall paper bag bottoming machine for valve bags and open-mouth bags used in the construction, chemical and food industries

- Max. speed 300 bags/min

- Bottom width 90-250mm

- Bag width 300-720mm

- Bag length 350-1650mm

We focused on reducing customer complaints during the final use of valve bags in the design of our valve bag bottomer machine. Through innovative design, stable operation of the main conveyor belt is ensured, with precision control within 1mm. This precision extends to the vertical cutter, where cutting errors are kept within 1mm. The world-first online adjustable vertical cutter allows for easy adjustments without stopping the machine. These innovations provide strong protection against dust emissions during the bag filling process, ensuring proper sealing and preventing powder leakage.

The valve bag bottomer machine also handles small-batch, multi-variety paper bag production efficiently. Changing bag specifications is quick and simple, with one-click adjustments, eliminating the need for gear replacements.

- Specifications

- Machine Construction

- Features

The valve bag bottomer machine is ideal for packaging a variety of materials, including:

- Cement Industry: Packaging for Portland cement, white cement, dry mixed cement, and premixed products

- Mining Industry: Packaging for calcium carbonate, gypsum, lime, and other powdered and granular materials

- Chemical and Petrochemical Industry: Packaging for building chemicals, casting powders, polymer granules, fertilizers, and organic fertilizers

- Food Industry: Packaging for flour, starch, grains, sugar, beans, and other food products

- Agriculture: Packaging for animal feed, seeds, coal, and other agricultural products

Improve production efficiency with high-performance packaging solutions.

Contact us today to explore how the Valve Bag Bottomer Machine can enhance your packaging process.

Applicable Bag Types

- Open-Mouth Paper Bag

- Kraft Paper Valve Bag with Thumb Notch

- Inner Sleeve Valve Bag

- Hot-Melt Glue Sealed Paper Valve Bag

- Ultrasonic Sealed Paper Valve Bag

| Model | |||

| Max. speed | 200 bags/min | 300 bags/min | 300 bags/min |

| Bottom width | 90-170mm | 90-180mm | 90-250mm |

| Bag width | 300-600mm | 300-600mm | 300-720mm |

| Bag length | 410-1300mm | 410-1300mm | 410-1450mm |

| Center distance | 260-1000mm | 200-1000mm | 200-1350mm |

| First valve sheet length (optional) | 90-270mm | 90-270mm | 90-270mm |

| Second valve sheet length (optional) | 90-270mm | 90-270mm | 90-270mm |

| Weight | 45T | 50T | 60T |

- 1. Feeding

- 2. Tube Aligning

- 3. Creasing & Bottom Opening

- 4. First Valve Unit

- 5. Second Valve Unit

- 6. Internal Patch Inserting

- 7. Bottom Pasting

- 8. Bottom Forming

- 9. Bottom Reinforcing Patch Inserting

- 10. Pressing

- 11. Counting & Stacking

The valve bag bottomer machine is mainly composed of thirteen parts, which are:

- Innovative Design

The newly designed valve bag bottomer machine uses analog digital control with a tool-free adjustment system. It features 50 servo motors, allowing for one-click switching between different paper bag specifications. - European-Sourced Components

20% of the components are sourced from Europe, featuring a synchronous belt drive design that requires no lubrication, meeting stringent pharmaceutical and food-grade workshop standards. - AI Vision Detection

Our innovative use of AI vision detection ensures quality control. The system automatically rejects bags if they are placed upside down, if the bottom size deviates too much, or if external reinforcement strips are missing, effectively reducing customer complaints. - Moisture Control

To manage moisture content in paper bags, we continuously improve the equipment. The valve bag bottomer machine now uses chemical adhesives, enabling faster drying of the bags and preventing issues like yellowing and mold.