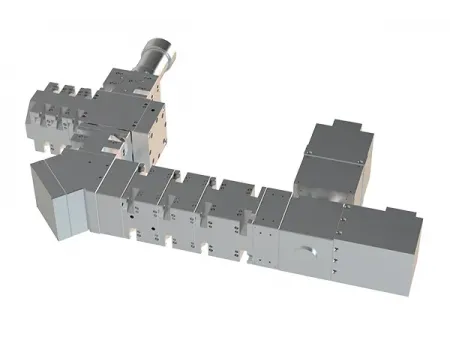

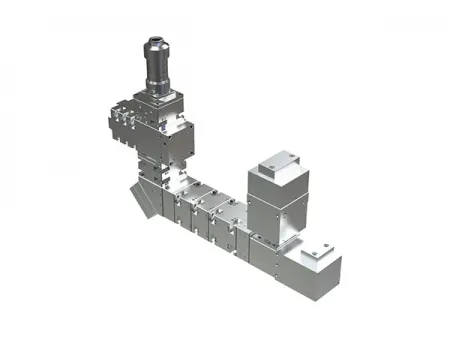

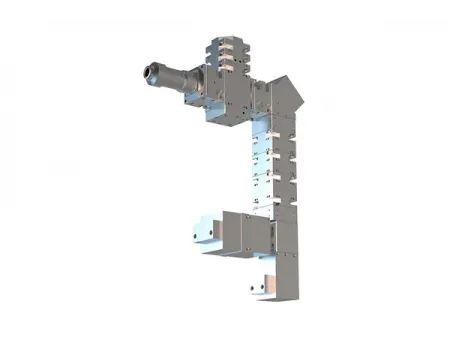

OMM-10000-1064 PP Real-time Laser Process Monitoring Module

Laser System Modules & Measurement Instruments

Online process monitoring of laser power and spot profile in laser welding, cutting and marking operations

OMM-10000-1064 PP real-time laser process monitoring module is a high-precision monitoring module designed for laser processing equipment. It enables real-time monitoring of the spot profile and power of the laser source from the processing head, ensuring the quality and stability of the laser welding process. This module precisely measures laser power and spot distribution, making it a key component for optimizing laser processing quality and enhancing production efficiency.

| Input Laser Requirements | |

| Incident beam divergence angle (mrad) | < 0.5 |

| Incident beam diameter (mm) | < 25 |

| Laser wavelength (nm) | 1064 |

| Incident laser power (kW) | 1-10 |

| Test Accuracy | |

| Laser power monitoring accuracy (%) | < 0.3 |

| Spot profile monitoring accuracy (%) | < 1 |

| Dimensions & Weight | |

| Dimensions (W x D x H) mm | 440×165×190 |

| Weight (kg) | 4 |

- Accurate monitoring

Precisely monitors laser spot profile and power through a high-power beamsplitter, attenuator group, and 32x magnifying lens group. - High stability

Real-time detection of laser power fluctuations ensures the stability of the laser output, adapting to the demands of high-power laser processing. - Flexible customization

Supports customizable interfaces to suit different equipment and application scenarios. - Broad applications

Suitable for a variety of laser processing equipment, including welding, cutting, and marking, with wide applications in industrial manufacturing, automotive, and aerospace.

By continuously monitoring laser power and spot profile, this module effectively improves processing accuracy and production efficiency, making it an indispensable core component of modern laser processing equipment.

This monitoring module integrates optical components such as a high-power beamsplitter, attenuator group, 32x magnifying lens group, and prism. Through beamsplitting technology, the laser beam from the processing head's source is guided to both a spot profiler and a photodetector. The 32x magnifying lens group allows for precise monitoring of the laser spot distribution, while the photodetector provides real-time monitoring of laser power and stability, detecting whether the laser output is in its optimal operating state.

- Laser welding, cutting, and marking.

- Laser process monitoring.