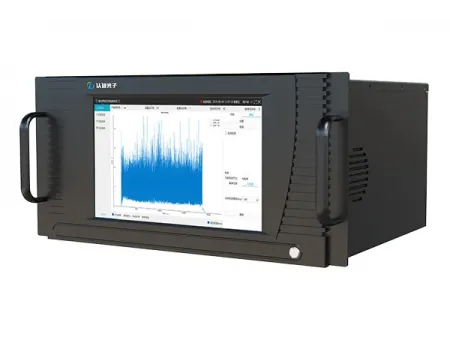

WMS-100-FIO 5-in-1 Laser Welding Process Monitoring Sensor

Laser Welding System Components

Process monitoring for laser welding

WMS-100-FIO 5-in-1 laser welding process monitoring sensor is a specialized sensor engineered to detect potential defects in the laser welding process. It achieves highly efficient weld quality monitoring by passively observing spectral radiation signals and actively emitting laser light to measure melt pool disturbance, focal length shifts, and other critical parameters. With a high sampling frequency of 100MHz and 16-bit accuracy, the WMS-100-FIO 5-in-1 laser welding process monitoring sensor is compatible with red, green, and blue lasers, enabling real-time monitoring and detection of various welding defects such as incomplete fusion, spatter, pores, inclusions, burn-through, and undercut.

| Monitoring Signals | |

| Passive capture | Plasma radiation,laser reflection,infrared radiation from the melt pool |

| Active measurement | Melt pool disturbance,keyhole depth |

| Signals | |

| Sampling frequency | Max. 100MHz |

| Sampling accuracy | 16-bit |

| Test Parameters | |

| Defect types | False wetting,spatter,gas pores,slag inclusions,burn-through and undercut. |

| Welding stability | Keyhole depth,time-frequency characteristics of keyhole oscillation ultrasound. |

| Compatibility | |

| Multi-band lasers | Blue laser,green laser and near-infrared (NIR) laser |

| Various welding heads | Galvanometer scanners,autogenous welding heads |

- Comprehensive multi-signal detection

A single system simultaneously detects five signals—plasma radiation, laser reflection, melt pool infrared radiation, melt pool disturbance, and keyhole depth—for real-time monitoring of weld depth and defects. - Exceptional high-precision monitoring

A sampling frequency of up to 100MHz and 16-bit accuracy can detect defects at a micron scale. - Wide compatibility

Compatible with blue, green, and infrared lasers, and supports both galvanometer scanners and welding heads.

Our system is engineered to excel in a wide range of applications, providing precise control and quality assurance for demanding processes.

- Online monitoring and closed-loop optimization for high-quality laser deep penetration welding of thick metals.

- Quality control and assurance for the laser welding of aluminum and die-cast aluminum alloys.

- Real-time quality inspection for high-speed welding of new energy and energy storage battery tabs and connectors.

- Online quality monitoring and closed-loop optimization for laser additive manufacturing systems.