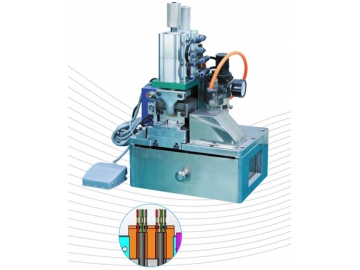

CO2 Laser Wire Stripping Machine

- CO2 Laser Wire Stripping Machine

Application

Application Application

Application

Application

CO2 laser wire stripping machine is used in cutting internal shield line in fields of mobile phones, computers, digital cameras, cars, electronic dictionaries and other microelectronics industries. It is good in cutting and stripping non-metal materials such as chloride of ethylene polymers, class fiber, polyester film (PET), fluoride, polyethylene, aluminum foil and can also be used in the protection layer of ordinary fiber, ribbon optical fiber in the communication industry. Also, it can be used in coating end stripping and intermediate stripping.

| Maximum average power of laser output | 30W*2 |

| Wavelength | 10.64um |

| Laser repetition precision | ±0.05mm |

| Energy instability | ≤2% |

| Maximum cutting speed | ≤600mm/min(various according to materials) |

| Stripping range | 100mm *100 mm |

| Carvings speed | 7000 mm/s |

| Software program | WIN+ specialized software |

| Mechanical precision of worktable | ±0.03mm/m |

| Repeatable positioning accuracy of X, Y and Z | ±0.02mm |

| Power supply demand | 220V±10%, 50Hz/30A |

| Control system | PC |

| Cooling mode | Wind |

Features

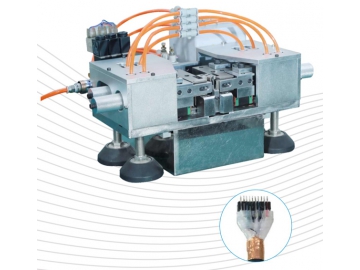

1.Adoption of dual-optical makes the stripping machine has high speed, large production and good efficiency.

2.Dual-optical asynchronous block alignment makes the machine has high cutting precision.

3.With a special suction system, the cutting residue can be effectively removed and the stability is high.

4.Cutting period, cutting area, cutting times, cutting graphics can be edited and saved arbitrarily.

5.The stripping machine can work alone as well as can be used in conjunction with the automated assembly line work.

Description

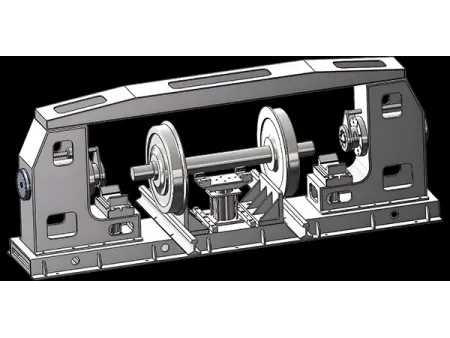

CO2 laser wire stripping machine is designed for stripping wire of metal shielding layer, specially works on processing micro coaxial cable. With high performance German IPG fiber laser adopted, the four-path laser will completely strip metal shielding layer wire without hurting insulator. The machine is stable and reliable under 24 hours continuous full load operation, which makes it high effective and low maintenance cost. With adoption of non-contact cutting, the position, size and depth can be accurately controlled to acquire high accuracy, which make sure good ability of stripping insulating layer, inner shielding layer and a variety of materials to reach the high rate of finished product. Cutting of multi pole line on the same axis among a large area, a plurality of fast in stripping communication and optical fiber protective layer and a coating layer cutting requirements can be satisfied.