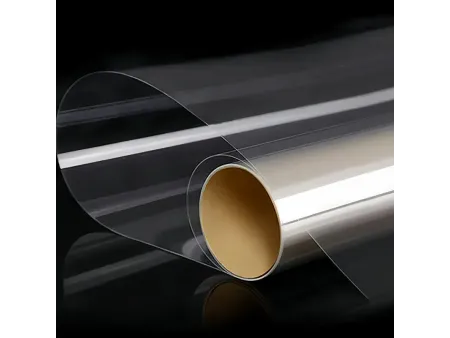

PET/PLA Plastic Sheet Extrusion Line

We have been engineering and refining PET/PLA plastic sheet extrusion lines with a strong focus on efficiency, reliability, and technological advancement. Designed to deliver consistent sheet quality with excellent transparency and stability, the system combines extrusion, calendering, and winding processes to convert raw pellets into sheets or roll stock ready for thermoforming. From cups and bowls to trays, blister packs, and stationery packaging, the plastic sheet extrusion machine provides manufacturers with a versatile and dependable solution for a wide range of thermoforming applications.

| Model | |

| Applicable material | PET/PLA |

| Production capacity | 300-450kg/h |

| Screw diameter | 75mm |

| Sheet thickness | 0.2-1.5mm |

| Die width | 1000mm |

| Effective sheet width | 850mm |

| Upper Calender | Ø320×1100mm |

| Middle Calender | Ø500×1100mm |

| Lower Calender | Ø500×1100mm |

| Rewinding method | Double rewinder |

| Max. rewinding diameter | 800mm |

| Total power | 350kW |

| Operation power | 200kW |

| Power Supply | 380V, 3 phase, 50Hz |

| Machine dimensions (L×W×H) | 32×6×4mm |

| Machine weight | 15t |

- Feeding system

- Ø75 mm parallel twin-screw extruder

- Hydraulic screen changer

- Metering pump

- Die head mould

- Three-roll calender

- Edge trim

- Silicone oil coating

- Dryer

- Traction unit

- Rewinder

- Electrical control system

-

- 1

High efficiency with large-capacity extrusion and low power consumption

-

- 2

Screw design with large L/D ratio ensures excellent plasticizing performance

-

- 3

Ergonomic design makes operation simple, reliable, and comprehensive in function

-

- PLC system

-

- Inverter

-

- Contactor

-

- Relay

-

- Screw & barrel diameter: Ø75 mm, twin-screw design

- Material: wear-resistant nitrided steel

- Screw hardness: HV950-1050

- Barrel cover: cast copper and cast aluminum for energy-efficient heat retention

- Heating power: 46.5 kW

- Cooling: circulating water pump system

- Pump motor: 0.55 kW

- Main motor: 132 kW AC motor

- Inverter: high-performance, constant torque, precise speed control

- Reducer: high-torque gearbox with direct motor drive

- Bearings: NSK (Japan)

- Mainframe: steel platform structure

Extrusion unit -

- Type: roots-roots-water ring pump, 3-stage system

- Ultimate vacuum: ≤10 Pa

- Maximum pumping volume: 150 L/s

- Operating vacuum: ≤300 Pa

- Tank material: stainless steel 304

- Equipped with feeding device, two vacuum degassing ports, and one natural degassing port

Vacuum pump system -

- Type: hydraulic screen changer

- Structure: double-column, two-station design

- Heating: stainless steel heating rods

Screen changer -

- Drive connection: cardan shaft connectors

- Drive system: gearbox AC motor

- Equipped with Italy Gefran pressure sensor for closed-loop speed control, ensuring high accuracy and durability

Gear pump -

- Die head width: 1000 mm

- Max sheet width: 850 mm

- Type: T-die with hanger runner (JC Time brand)

- Material: high-quality die steel

- Runner surface: chrome-plated, thickness 0.03-0.05 mm

- Surface finish: polished to mirror (cavity Ra 0.1 µm, die lip Ra 0.05 µm)

Die head -

- Roller coaxiality: ≤0.005 mm

- Roller surface finish: Ra ≤0.016 µm

- Surface hardness: HRC58-62

- Chrome plating thickness: ≥0.08 mm

- Structure: horizontal J-type, three-roll calender

- Frame: solid steel plate; Bearings: NSK (Japan)

- Drive: independent motor control for each roll, adjustable individually or simultaneously

- Motor power: 4.4 kW

- Bearing type: spherical ball bearings (NSK, Japan)

- Pressing: hydraulic open/close with manual worm gear fine adjustment (self-locking)

- Safety: emergency stop switch and synchronous control system

Calender system -

- Cooling medium: softened and purified water

- Control range: room temperature to 100 °C

- Accuracy: ±1 °C

- Pump power: 4 kW stainless steel pump

- Condenser: double-parallel type for enhanced cooling

- Valve: pneumatic angle seat valve

- Installation: mounted on cooling bracket for easy access and maintenance

Roller cooling system -

- Bracket length: 5 m

- Pulling rollers: aluminum, Ø70 × 1000 mm

- Trimming device: 2 round knives

- Waste edge winding device: 2 sets

- Static eliminator: 1 set

- Online crusher with air delivery: 1 set

Edge trimming unit -

- Four-roll coating system, double-sided application

- Sealed oven drying method

Silicon oil coating unit -

- Double-station flip design

- Control: automatic fixed-length counting

- Max roll diameter: ﹤800 mm

- Paper core: 3 inches

Rewinding system -

- PLC with touchscreen interface for easy operation

- Emergency stop button for operator safety

- Intelligent temperature control module with Taiwan solid-state relay

- High-precision temperature control

- Extruder motor: stable speed, high transmission performance

- Rollers driven by motor and reducer: hard gear, high torque, high speed, low noise

- Auxiliary drive system: high precision, low-frequency torque control

- Electrical cabinet protection grade: IP21

Control system

- ATS-85 PET Plastic Sheet Extruder Machine

- ATS-75 PLA Sheet Extrusion Machine