Profile Bending Machine / Angle Roll

Profile Rolling Machine, Angle Rolling Machine, Plate Rolling Machine, Metal Sheet Bending Machine, Section Bending Machine

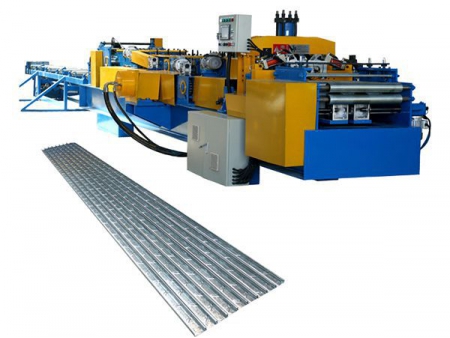

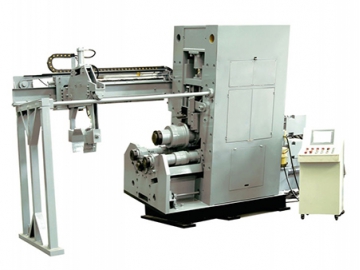

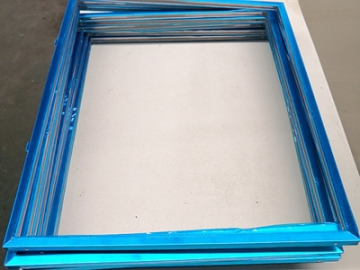

For this profile rolling machine, all of the 3 rolls are driving rollers and are powered by hydraulic motors and gears. Both the 2 side rolls driven hydraulically are designed to perform arc motion around a fixed axis. A carrier roll and a correcting guide roll are respectively arranged at both sides of the working rolls to ensure the rolling quality of asymmetric cross section (such as angle iron). The profile bending machinery is able to roll various sections, including U-beam, angle steel, flat steel, circular tube, square tube, etc.

As a curved 3-roll section bending machine, the equipment is professional in pre-bending sections of metal plates perfectly. It is mainly comprised of side rolls, a carrier roll, a transmission part, an electric part, a hydraulic system and dies.

Features of standard plate bending machine

• The bending machine is forged using high-strength wear-resistant molds. It is given heat treatment and submitted to non-destructive structural control

• Digital display is adopted for all shafts

• 3 driven shafts

• Heavy-duty steel welded frame without stress

• All operations are conveniently controlled by an independent control console

• High-power hydraulic motor

• Both horizontal and vertical working rolls

• Extended shafts for correction

Features of optional plate rolling machine

• Mobile control panel

• Oil cooling system

| W24S- Profile Bending Machine Technical Parameters | |||||||||||||

| Model | 6 | 16 | 30 | 45 | 75 | 100 | 140 | 180 | 260 | 320 | 400 | 500 | |

| Max elastic section modulus (cm3) | 6 | 16 | 30 | 45 | 75 | 100 | 140 | 180 | 260 | 320 | 400 | 500 | |

| Rolling speed (m/min) | 6 | 6 | 6 | 6 | 5 | 5 | 5 | 4 | 4 | 4 | 4 | 4 | |

| Profile Yield Strength (Mpa) | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | |

| Max section of angle bending | 40×5 | 70×8 | 80×8 | 90×10 | 100×10 | 120×12 | 140×16 | 150×16 | 160×16 | 180×14 | 200×18 | 200×20 | |

| Min bending diameter | 800 | 1000 | 1200 | 1500 | 2000 | 2400 | 2500 | 2600 | 2600 | 3600 | 3600 | 4000 | |

| Max section of angle bending | 50×5 | 80×8 | 90×10 | 100×10 | 120×12 | 140×16 | 150×16 | 160×16 | 180×14 | 200×18 | 200×24 | 250×25 |

| Min bending diameter | 800 | 1000 | 1100 | 1300 | 1600 | 1800 | 2200 | 2000 | 2500 | 3600 | 3600 | 4000 | |

| Max section of C-channel bending | 8# | 12# | 16# | 20# | 25# | 28# | 30# | 32# | 36# | 40# | 45# | 50# |

| Min bending dia. | 600 | 800 | 800 | 1000 | 1100 | 1700 | 1200 | 1500 | 1800 | 2000 | 2000 | 2400 | |

| Max section of C-channel bending | 8# | 12# | 16# | 20# | 25# | 28# | 30# | 32# | 36# | 40# | 45# | 50# |

| Min bending dia. | 700 | 900 | 1000 | 1150 | 1600 | 1700 | 1700 | 1800 | 1800 | 2000 | 2000 | 2000 | |

| Max section of bending flat bar | 100×18 | 150×25 | 180×25 | 200×30 | 220×40 | 250×40 | 280×50 | 300×50 | 330×50 | 360×60 | 400×75 | 500×76 |

| Min bending diameter | 600 | 700 | 800 | 900 | 1000 | 1200 | 1300 | 1500 | 1900 | 2000 | 2400 | 2400 | |

| Max section of bending flat bar | 50×12 | 75×16 | 90×20 | 100×25 | 110×40 | 120×40 | 150×40 | 180×30 | 190×40 | 190×50 | 200×50 | 200×60 |

| Min bending diameter | 500 | 760 | 800 | 1000 | 1100 | 1300 | 1500 | 2000 | 2000 | 2400 | 2200 | 2500 | |

| Max section of bending pipe | 42×4 | 76×4.5 | 89×5 | 89×8 | 114×5 | 159×5 | 168×6 | 168×8 | 219×8 | 245×8 | 273×8 | 323×10 |

| Min bending diameter | 500 | 750 | 900 | 900 | 1200 | 2000 | 2000 | 2000 | 3500 | 3000 | 3500 | 4200 | |

| Max section of bending round steel | 38 | 52 | 62 | 75 | 85 | 90 | 100 | 110 | 120 | 135 | 150 | 160 |

| Min bending diameter | 450 | 600 | 600 | 800 | 1000 | 1100 | 1200 | 1300 | 1350 | 1800 | 2000 | 2000 | |

| Max section of bending square | 45×3 | 60×4 | 70×4 | 80×6 | 90×8 | 100×10 | 125×10 | 140×10 | 150×10 | 165×10 | 180×12 | 200×12 |

| Min bending diameter | 750 | 900 | 1000 | 1200 | 1600 | 2000 | 2500 | 3000 | 3000 | 3500 | 3500 | 5000 | |