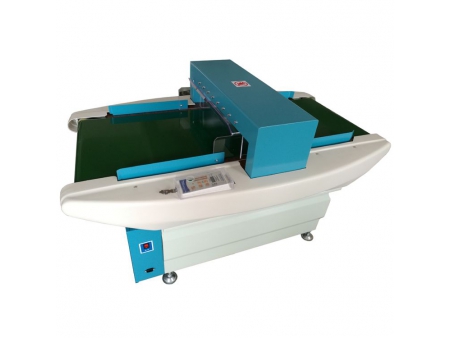

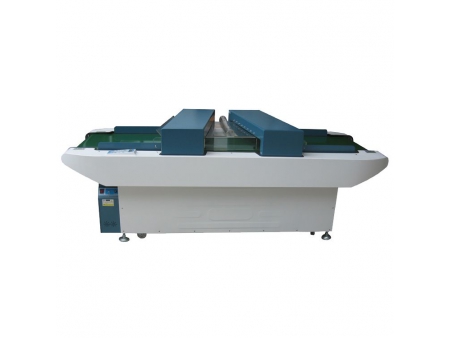

Conveyor Belt Needle Detector

Request a Quote

Metal Detection Equipment

Metal detection system for detecting broken needle fragments in textile and apparel

Conveyor belt needle detector is based on the principle of magnetic induction to identify ferromagnetic metal impurities mixed in products. When the system detects metal impurities, it sends a signal to the equipment's control system to alert and prompt the removal of non-conforming products. The purpose of the needle detector is to ensure that textiles do not contain sharp metal objects such as broken needles that may threaten user safety. All textiles and wearable items need to be inspected before entering the sales channel to avoid threats to consumer safety due to broken needles and the resulting substantial claims and intangible loss of brand image.

Conveyor Belt Needle Detectors We Offer

- Conveyor Needle Detector

- Double Head Needle Detector

- Wide Belt Conveyor Needle Detector

- Needle Detector with High Aperture Height

- Digital Needle Detector

- Flatbed Needle Detector

- Handheld Needle Detector

Applicable Products

- Knitwear products include children's wear, men's and women's wear, denim, underwear/bras, knitwear, gloves, etc.

- Footwear, leather, plastic products, toys, etc.

- Bedding includes mattresses, bed sheets, duvet covers, carpets, etc.

- Special materials such as non-woven fabrics, leather, fabrics, yarns, etc.

Specifications

| Detection Principle | Balanced coil (based on the principle of electromagnetic induction) |

| Tunnel Size | Width: 400-2000mm (customizable) Height: 80-600mm (customizable) |

| Optimal Sensitivity | Fe: Ø0.8mm |

| Alarm | Acoustic alarm |

| Power Source | AC220V; 50Hz; 1Phase |

Features

- Conveyor belt needle detector can precisely detect ferromagnetic broken needle fragments in textile and apparel.

- Avoid damage or downtime for downstream production equipment maintenance.

- Free-of customer complaints and product recalls, avoiding losses.

- Low equipment maintenance cost, long service life, and quick recovery of equipment costs.

- Nearly 20 years of technological accumulation, our needle detector comes with stable performance and good sensitivity.

- Needle detector has counting and statistical functions, with optional report printing capability.

- Customizable needle detector with different channel sizes is available.

Optional

- Conveyor

- Touchscreen

- Printer

- Rejection mechanism (air-blast rejection, push-plate rejection, inclined conveyor belt rejection, powered roller conveyor rejection)

FAQ

Conveyor belt needle detector is suitable for metal foreign object detection in packaged or bulk products. In order to accurately determine suitability, buyers need to provide necessary information such as the name of the tested product, maximum packaging size, production capacity, and any specific sensitivity requirements. Please contact SINBON's sales team for assistance in confirming the appropriate machine configuration.

While local service points are limited, buyers may seek assistance from local dealers, if available. Prior to leaving the factory, the machine undergoes complete assembly and testing and is shipped fully assembled, requiring no special installation or debugging. Simply power on the machine for use and reference the manual or instructional videos for parameter settings. In the event of any issues, contact the seller for online guidance and support.

Our conveyor belt needle detector comes with a 12-month warranty, excluding consumable parts. Within the warranty period, replacement parts are provided at no additional cost (excluding shipping expenses), while reasonable fees apply for parts outside the warranty coverage. Lifetime free remote technical support is also offered for the equipment.

Contact us promptly for assistance in resolving the issue. We can conduct real-time remote fault diagnosis and promptly ship replacement parts if needed.