Label Finishing Machine, DBGS-320/370

Request a Quote

Label printing, die cutting and slitting machine

The label printing, die cutting and slitting machine by Daba Machinery features the latest full rotary/semi-rotary die-cutting switch-ability. The label finishing machine operates at a maximum speed of 120m/min for full rotary die-cutting and 60m/min for semi-rotary die-cutting. With a variety of optional accessories available, the finishing machine can meet diverse customer needs, including the addition of inspection systems, cross-cutter, IML die-cutter, turret rewinder, etc.

Applicable Materials

Thermal paper, self-adhesive labels, non-woven fabrics, plastic films, etc.

Applications

Suitable in deep processing of electronic, automobile, medical and printing products.

Features

- Each component is equipped with high-quality Panasonic servo motors to ensure stable and efficient machine operation.

- The label finishing machine is equipped with flexographic printing unit, intermittent die-cutting unit, slitting unit, etc. The machine is capable of performing cold foil stamping, varnishing, laminating, and printing for flexo printing tasks.

- Advanced servo control system and user-friendly operator panel significantly enhance product quality and production efficiency.

- Utilizing the latest full rotary and intermittent rotary exchange technology, suitable for digital printing label processing.

Specifications

| Model | DBGS-370 | DBGS-320 |

| Maximum Substrate Width | 370mm (14.56") | 320mm(12.60”) |

| Maximum Unwinding Width | 800mm (31.5") | 800mm (31.5") |

| Maximum Rewinding Width | 800mm (31.5") | 800mm (31.5") |

| Maximum Flexo Printing Width | 350mm (13.77”) | 350mm (13.77”) |

| Maximum Die Cutting Width | 350mm (13.77") | 350mm (13.77") |

| Maximum Speed (Full Rotary) | 120m/min | 120m/min |

| Minimum Speed (Semi-rotary) | 60m/min | 60m/min |

| Maximum Flexo Printing Speed | 60m/min | 60m/min |

| Printing Cylinder (Optional) | 80T-210T | 80T-210T |

| Printing Cylinder (Standard) | 140T | 140T |

| Self-adhesive Die Cutting Accuracy (First Layer) | ±0.15mm | ±0.15mm |

| Die Cutting Accuracy | ±0.25mm | ±0.25mm |

| Die Cutting Positioning | Color sensor | Color sensor |

| Magnetic Cylinder (Optional) | 80T ~ 210T | 80T ~ 210T |

| Magnetic Cylinder (Standard) | 140T | 140T |

| Total Power | 19 ~ 21kW | 19 ~ 21kW |

| Air Pressure | 0.6 kPa | 0.6 kPa |

| Rated Voltage | 380V, 50Hz | 380V, 50Hz |

| Rated Current | 50A | 50A |

| Weight | 3200kg | 3200kg |

Details

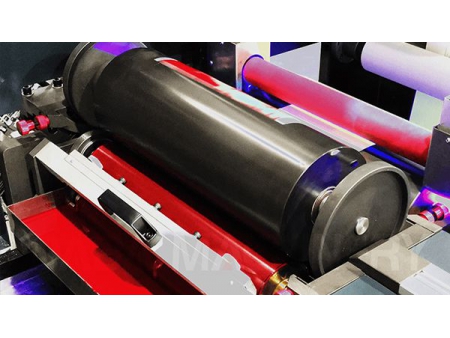

- Flexo Printing Unit

(Panasonic Servo Motor Driven)

- Full rotary printing unit

- One 140T printing cylinder (standard)

- Ceramic anilox roller

- Chilling drum

- UV dryer

- Die Cutting Unit

(Panasonic Servo Motor Driven)

- Full/Semi-rotary mode switchable

- One 140T printing cylinder (standard)

- Magnetic cylinder with adjustable lifting spring

- Color sensor

- Full-Contact Waste Removal Unit

- 3-inch air expanding shaft

- Winch-driven roller with adjustable tension control

- Slitting Unit

- 6 sets of slitters (optional)

- Round/Square slitters (optional)

- Exhaust blower

- Scale roller for manual adjustment of slitting width

- Rewinding Unit

- Rewinding shaft (standard)

- 1-inch/1.5-inch air expanding shaft (optional)

- Automatic taper tension control

- Automatic counter

- Web Guide

- Movable design

- 10-inch display

- English or other languages available

- Panelmaster (standard)

- Proface (optional)

Optional

- Label Matrix Removal System

- Dust Removal System

- Corona Treater

- Reverse-Side Printing Mechanism

- Slitting & cut-to-length unit

- Adjustable Bottom Rollers

- Die-Cutting Pressure Gauge

- Collection Table

- Cold Foil Stamping Unit

- Automatic Knife Adjustment System