Altitude Test Chamber

Applications:

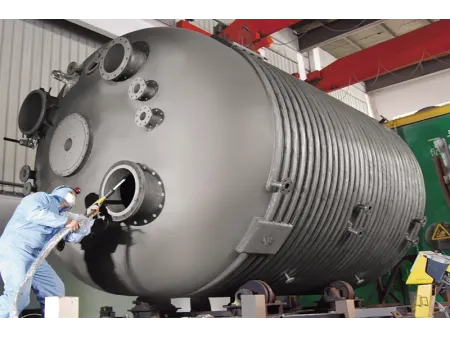

Altitude test chambers are usually used in space, information, electronic and other industries to test and determine that materials, components, and equipment are all adaptable and reliable to high/low temperatures, low pressure, or a combination of those in extreme environments. The altitude test chamber consists of an insulation can, refrigeration system, vacuum system and circuit controller with an integrative structure.

The series of altitude testing chambers uses a balanced temperature and humidity control system (BTC), which uses a PID formula to calculate how to reduce the power down to zero, and decrease the resistor temperature as it reaches the set point. This ensures the temperature levels do not rise above or fall below the preset temperature.

Features

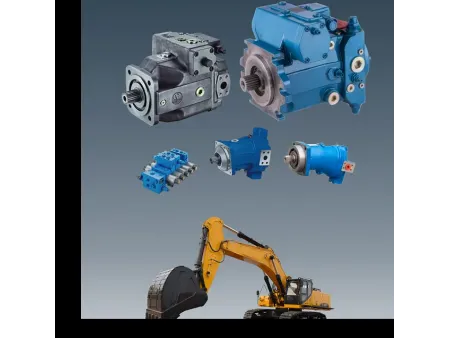

- The key components of the altitude test chamber are all sourced from internationally known brands, thus ensuring the machine is reliable and has a long service life.

- The refrigeration system plate heat exchanger is efficient.

- The efficient oil separator ensures the compressor's long service life.

- Experimental data and profiles can be download by a U disk.

- Don't worry if a power failure happens, as the machine will remember previous operation settings. Users can choose to stop, continue or reset the testing when power returns.

- Customers can set a time, and the machine will automatically begin to operate at that time after turning on the switch.

- Users can connect the machine to the internet using a computer software program, allowing users to remotely control the equipment, download experiment data, and control a number of equipment pieces on a production line.

- Our altitude test chamber features malfunction alerts, power off protection, set time and other attractive capabilities.

- Refrigeration system

Inner tank

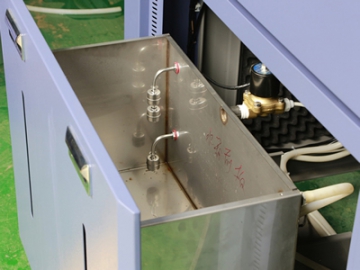

Inner tank  Water tank

Water tank Internet port

Internet port

Material:

Exterior: high quality varnished carbon steel plate

Interior: SUS304# rough stainless steel

Insulated material: hard PU foam board + glass fiber

Refrigeration technique:

1. We use nitrogen as the shielding gas during welding, use a rotary vane pump with two rotors to maintain a vacuum status, and ensure the refrigeration system's interior is clean and reliable.

2. A tray is installed in the bottom of compressor and condensed water is drained out through the draining pipes.