Low Voltage Variable Frequency Drive

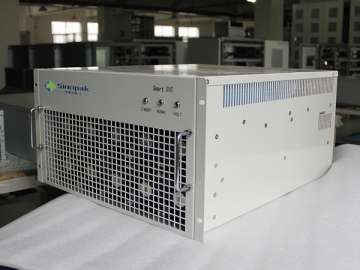

Through years of research and development, we have accumulated riche experience in industrial automation application. Combined with world-class drive technology, we make ES series high-performance vector-based variable frequency drive. Based on its superior performance, rich functionality and perfect structure, it can meet needs of industrial control in the harsh environment in different areas. It features excellent quality, user-friendly man-machine interface and convenient services, which make it competitive on the market.

-

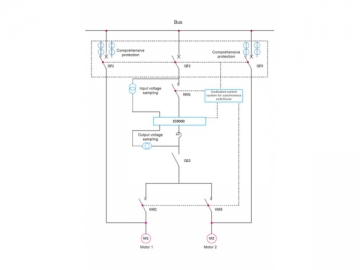

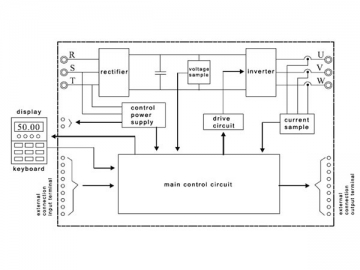

Composition

Composition -

Principle

Principle

| Type | Performance | Target market | Series | Appearance |

| High performance vector | 1) Excellent performance; 2) Rich functions; 3) High reliability; 4) Comprehensive and systematic protection functions; 5) Intelligent LCD keyboard included in standard configuration; 6) Built-in various industry application standard macros; 7) Simple servo function. | Hoisting and lifting Digitally controlled machine tools Forging machine tools Roots blower Food machinery Textiles Dyeing and finishing Plastic machine HVAC, Petroleum Chemical engineering Medical, etc. | ES 850 220 V 0.4-2.2 KW 380 V 0.75-560 KW 690 V 1 5-560 KW |  |

| Economic and general | 1) High reliability; 2) High usability; 3) Compatible with permanent magnet synchronous motor drive and three-phase asynchronous motor drive; 4) Intelligent LCD keyboard included in standard configuration; 5) Modular compact structure design | Ceramic equipment Dyeing and finishing equipment Centrifuge Textiles Fans Pumps, etc. | ES 580 220 V 0.4-2.2 KW 380 V 0.75-560 KW 690 V 1 5-560 KW |  |

| Compact and simple | 1) Small size and compact; 2) Easy commissioning, optional intelligent LCD keyboard; 3) Built-in RS 48 5/CANopen communication included in standard configuration; 4) High-performance PID function; 5) Built-in encoder interface, supporting speed close-loop control | Small water pumps, Food packing, Food processing Woodworking and engraving Air blower, etc. | ES 350 220 V 0.4-2.2 KW 380 V 0.75-4 KW |  |

Features

1. Innovative Thermal Design Philosophy and Professional Thermal Simulation Analysis

2. Rigorous Temperature RiseTest on the Whole Converter

3. Spraying Process of Conformal Coatings

4. High Protection Grade

5. High Anti-interference Capability

6. Wide Voltage Range Design

7. Innovative and Independent Air Duct Design

8. Qualified Key Components

9. Comprehensive Motor Drive Technology

10. Accurate and Comprehensive Self-learning Function

11. Built-in Servo Function

12. Large Start-up Torque

13. Fast Torque Response, Low Torque Pulse

14. Wide Speed Range, High Steady-speed Precision

15. High Overload Capacity

16. LCD Smart Keyboard Adopted in Standard Configuration

17. Rich Industrial Application Micros

18. Reliable Braking Function

19. Rich Extension Functions

20. Rich I/O Interfaces

21. Systematic and Comprehensive Protection Functions

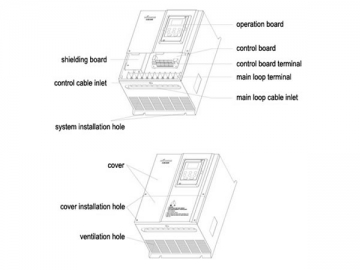

22. Compact Structure Design

23. Various Mounting Modes

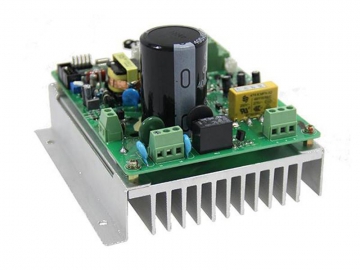

24. Modular Design

25. Unique SmartDrive

| Item | Specification and Technical Data | ||

| Main power connection | Input voltage U1 | 220...240V; 380...500V; 660...690V; 220V/380V/660V±20%; Single/three-phase power | |

| Input frequency f1 | 50...60Hz ±5Hz | ||

| Output voltage U2 | 0...U1 (V)(The maximum output voltage equals the input power voltage.) | ||

| Output frequency f2 | 0-1000Hz (V/F control); 0-500Hz(vector control) | ||

| Basic functions | Carrier frequency | 2-12 KHz (The device can intelligently and automatically make optimal adjustment according to load characteristics and drive temperature.) | |

| Input voltage unbalance degree | Maximum: ±3% of rated inter-phase input voltage | ||

| Efficiency | About 98% (when operating at rated power) | ||

| Maximum frequency | 0-500Hz(vector control) 0-1000Hz (V/F control) | ||

| Input frequency resolution | Digital setting: 1RPM Analog setting: 0.025% of maximum RPM | ||

| Control mode | Open-loop V/F control Open-loop vector control (SVC)/close-loop vector control (FOC) | ||

| Startup torque | 200% @ 0.25Hz@ Open Loop(open-loop control) 200% @0Hz@ Close Loop(close-loop control) | ||

| Speed range | 1:200 @ Open Loop(open-loop control) 1:3000 @ Close Loop(close-loop control) | ||

| Steady-speed precision | ±0.5% @ Open Loop(open-loop control) ±0.01% @ Close Loop(close-loop control) | ||

| Overload capacity | Heavy load application: 60s at 150% rated current @40°C. The time depends on the drive temperature under other conditions. Light load application:60s at 110% rated current @40°C. The time depends on the drive temperature under other conditions. | ||

| Enhancements | Torque boost | Automatic torque boost. Manual torque boost 0.1%-30% | |

| V/F curve | Intelligent adaptive | ||

| V/F separation | Two methods: full separation, half separation | ||

| Acceleration and deceleration curves | straight-line or S-curve acceleration and deceleration method Two acceleration time values. The acceleration and deceleration time range:0.0s-650.00s | ||

| Simple PLC function | Achieve operation of up-to-16-stages speed(via built-in PLC or control terminals) | ||

| Built-in PID | Conveniently achieve the process control close-loop control system | ||

| Automatic voltage regulation (AVR) | When the grid voltage changes, the device automatically maintains constant output voltage. | ||

| Over-voltage and over-current stall control | The current and voltage are automatically limited during running to avoid jump faults due to frequent over-current and over-voltage | ||

| Fast current limiting | Over-current faults are minimized to guarantee normal operation of the frequency converter. | ||

| | Torque limiting and control | The torque is automatically limited operating (to avoid frequent over-current jumping fault due to too large torque). | |

| Protection function | Output short-circuit protection, input & output phase loss protection, over-current protection, Over-voltage protection,under-voltage protection, overheat protection, overload protection, brake chopper overload protection, brake chopper short-circuit protection, brake resistor overload protection | ||

| Non-stop during transient interruption | Keep the frequency converter operating in a short time (by reducing feedback energy compensation voltage at the moment of power outage). The duration depends on the mechanical inertia of the load at that time. | ||

| Timing control | Timing control function. The time range and precision is 0.0-6500.0(min). | ||

| Switching multiple motors | Support switching among four groups of motor parameters. | ||

| Bus communication | The standard configuration uses the built-in Modbus/CANopen communication, which can be extended to Profibus-DP bus communication. | ||

| Intelligent temperature control | Full cover system temperature testing, intelligent real-time IGBT chip temperature monitoring, and intelligent and optimized adjustment of the carrier and current based on drive temperature changes | ||

| Type of encoders supported | Support differential encoders, collector open encoders, UVW encoders, rotary transformer encoders and Sin-Cos Encoders | ||

| Item | Specification and Technical Data | ||

| I/O Input/Output Interface | Command input mode | Control keyboard input, control terminal input, bus communication input, which can be switched mutually. | |

| Speed giving mode | Digital giving, analog voltage (current) giving, pulse giving, bus communication giving and PID giving, which are mutually switched. | ||

| Input terminal (input) | The followings are included in standard configuration: 6(F0) / 7 (F1 and above) digital input terminals, where, DI6 (FO) Dl7 (F1 and above)supports the maximum of 50 kHz high-speed pulse input. 2(F0) /3 (F1 and above) analog input terminals (where, at least 2 supports 0-10Vvoltage input or 0-20mAvoltage input) The followings are extended as cards: 5 digital input terminals 2 analog input terminals, supporting input of -10V to 10V voltage | ||

| Output terminal (output) | The followings are included in standard configuration: 1 high-speed pulse output terminal (supporting0-50 kHZ square signal output) 1(F0) /2(F1 and above) digital output terminals 1(F0) /2(F1 and above) relay output terminals 1 (F0) /2 (F1 and above) analog output terminals (supporting0-10V voltage output or 0- 20mA voltage output) The followings are extended as cards: 3 digital output terminals 3 relay output terminals 3 analog output terminals, supporting 0-10V voltage output or 0-20mA voltage output | ||

| Display and control | Man-machine interface | 5-bit 8-shape digital tube (F0), intelligent sealed LCD control keyboard (F1 and above) | |

| Parameters duplicating | Rapidly duplicating parameters via the LCD control keyboard | ||

| Application environment | Application site | Indoor, free of direct sunshine, dusts, corrosive gases, flammable gases, oil mist, water vapor, drip or salts | |

| Altitude | At 0-1000m;When the altitude is 1000-4000m, the capacity is reduced by 1% as the altitude rises by 100m. (consult professionals for more accurate values) | ||

| Operation ambient temperature | -10℃ to 40℃ (when the ambient temperature is 40℃-55℃, the drives automatically derated to achieve self-protection) | ||

| Relative humidity | Less than 95%RH. No droplets condensed (condensation) | ||

| Sinusoidal vibration | (IEC 60068-2/-6.Test Fc) Max.0.1mm (5tol3.2Hz);max.7m/s2 (13.2to 100 Hz)sinusoidal vibration (F0-F7) Max.0.1mm (10to57Hz);max.l0m/s2 (57to 150Hz) sinusoidal vibration (F8-F9) | ||

| | Impact | Not allowed (during operation); maximum 100m/s2,11ms(during storage and transportation with packing) | |

| Free fall (Max.) | Not allowed (during operation); with packing: 100cm @F0-2,76cm@F0-4,46cm@F5-7,15cm@F8-9 | ||

| Storage & transportation temperature | -40℃ to 70℃ (-40 to 158°F) | ||

| Protection grade | IP20 (UL open type), full closed design for small- and medium-power models. Top/Left and right sides can reachIP41 (the medium cavity with air vents on two sides for someF0**models) | ||

| Cooling mode | Forced air cooling of the interior fan. The air flows from bottom to top. Air-cooled radiator. | ||

| Application standard | IEC 61800-3 (2004), IEC61800-5-1 (2007);GB12668 (see the nameplate for details). | ||

Related Names

Frequency converter, frequency inverter, variable frequency drives, variable speed drives, variable voltage variable frequency drives, motor drives, AC drives