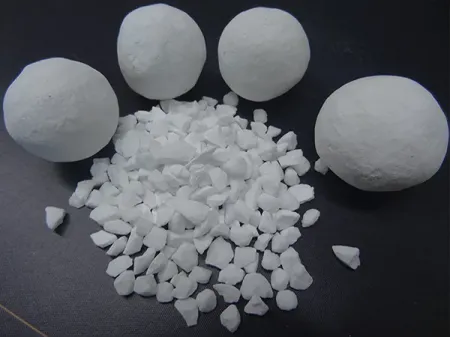

Tabular Alumina

Tabular alumina is a pure sintered alumina, thoroughly calcined without the addition of any additives such as MgO or B2O3. It boasts a coarse, well-developed α-Al2O3 crystal structure, with an Al2O3 content exceeding 99%. Characterized by a plate-like crystal structure and numerous closed pores, its purity, high thermal stability, and minimal reheating shrinkage contribute to its exceptional properties. After high-temperature treatment, it exhibits excellent thermal shock resistance and flexural strength.

Tabular alumina characteristics: high refractoriness; excellent corrosion resistance; superior erosion resistance; exceptional thermal shock resistance; high strength and good toughness; stable chemical properties.

Applications

Tabular alumina finds diverse applications, serving as a primary component in refractory materials like alumina-carbon, alumina-magnesia-carbon, magnesia-alumina-carbon, magnesia-spinel, and alumina-chrome refractory bricks. It is also utilized to enrich the alumina content in high-alumina shaped refractory materials. Its widespread use spans industries such as steelmaking, foundries, ceramics, and beyond, with extensive application throughout the entire iron and steel production process.

Available Size

| Fraction | 5-10mm, 8-5mm, 3-6mm, 3-5mm, 3-2mm, 1-3mm, 1-2mm, 0.5-1mm, 0.2-0.6mm, 0-0.5mm, 0-0.2mm, 14-28#, 28-48# |

| Fine Powder | 100#-0, 200#-0, 325#-0, 45μm-0, 0-0.045mm |

(other sizes are customizable)

Typical Chemical Analysis/Physical Properties

| Size | Chemical Index | Physical Index | |||||

| Al2O3% | SiO2% | Fe2O3% | Na2O% | Volume Density | Water Absorption | Apparent Porosity | |

| 0-1mm 1-3mm 3-5mm 5-8mm | 99.2min | 0.1max | 0.1max | 0.35max | 3.5g/cm3 | 1.5 | 5 max |

| 200#-0 320#-0 325# | 99min | 0.15max | 0.1max | 0.4max | 3.45g/cm3 | 2.0 | 6 max |

Production Flow

- Use 60# imported aluminum powder from Australia

- Employ a ceramic ball mill for the manufacturing process

- Produce tabular alumina balls

- Form tabular alumina ball cylinders

- Dry the tabular alumina balls

- Sintered tabular alumina ball by high temperature treatment

- Obtain sintered balls

- Proceed with sand making

Packaging

- 25kg small bag, filled by weight.

- Packaging in bulk bags.

- Combination of 25kg small bags and bulk bag packaging.