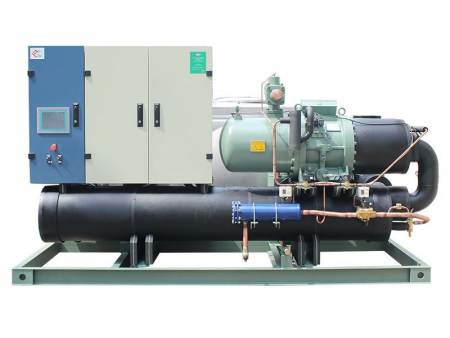

The refrigerator condenser welding line is primarily utilized for manufacturing wire-on-tube condensers made of iron wires and serpentine tubes. This automatic welding line includes essential equipment such as a high-speed wire straightening and cutting machine, steel tube cutting machine, steel tube bending machine, condenser welding machine, condenser folding machine. It enables the automated mass production of condensers, streamlining the manufacturing process for enhanced efficiency and precision.

Refrigerator Condenser Welding Line

- Straightening and cutting wire

- Straightening and cutting tubes, bend up to 12 tubes at a time

- Manually place wires and tubes into the welding fixture

- Get started with welding

- Fold the wire-on-tube condenser

-

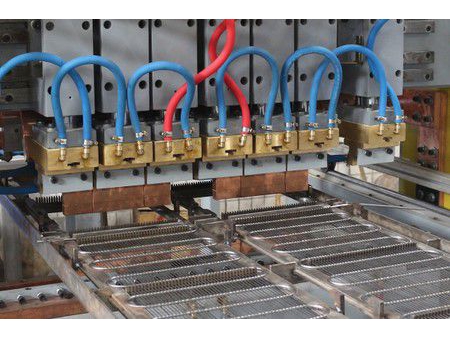

Multi-head welding machine

Multi-head welding machineThe latest medium-frequency inverter power supply for welding is designed with a focus on energy efficiency. Tailored to various products, it accommodates different numbers of welding heads based on specific design parameters. The efficiency of the system increases with the addition of more power supplies, resulting in faster working performance. The machine setup includes a single side double-layer material rack, enabling a continuous cycle of work with one side dedicated to welding and the other to loading and unloading of materials.

- Welding power: 160KVAx2

- Frequency: 1000HZ

- Maximum short-circuit current: 38000A

- Welding size: 600x1200mm (can be customized)

-

Steel wire straightening & cutting machine

Steel wire straightening & cutting machineThe machine is used for straightening and cutting of iron wire, just input the corresponding length and the machine will cut automatically.

- Voltage: 380V50Hz

- Applicable wire diameter: 1.1-1.5mm

- Length: 50-5000mm

- Speed: 80m/min

- Precision: ± 0.5mm

-

Steel pipe straightening & cutting machine

Steel pipe straightening & cutting machineThis machine is used for straightening and cutting of steel pipes, just input the corresponding length and the machine will cut automatically. It can be used for straightening and cutting of bundy pipe, steel pipe, copper and aluminum pipe. Changing mold is needed when performing straightening and cutting for pipes with different diameters.

- Voltage: 380V50Hz

- Applicable pipe diameter: 3-10mm

- Pipe wall thickness: 0.4-1.5mm

- Speed: 60m/min

-

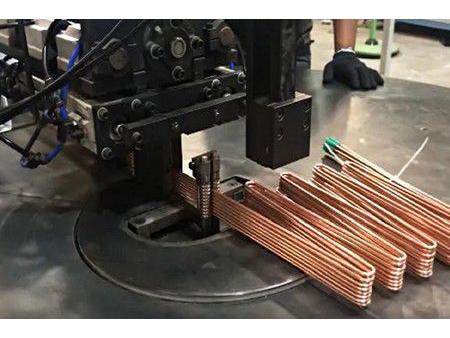

Serpentine pipe bending machine

Serpentine pipe bending machineIt executes the automatic feeding and bending of bundy pipes, allowing for the customization of bending angles based on product specifications. The system features easy programming, offering high levels of automation and efficiency.

- Voltage: 220V50hz

- Applicable pipe diameter: ¢3~¢10mm

- Bending angle: R7.5-R50

- Bending number at a time: 1-12

- Utilization of medium-frequency inverter power supply: The implementation of a medium-frequency inverter power supply results in substantial energy efficiency, contributing to significant energy savings during operation.

- Adjustable welding size: The welding line allows for the customization of welding efficiency and size parameters based on the specific production requirements. This adaptability ensures optimal performance in varying manufacturing scenarios.

- High automation level: The system achieves a high degree of automation, enabling a seamless execution of operations such as straightening, cutting, and welding. This level of automation enhances overall production efficiency and consistency while minimizing manual intervention.

- Upon the purchase of our welding equipment, we offer these four things: Chinese and English manuals, circuit diagrams, installation videos, and operation videos.

- Our welding engineers are available for 24-hour online guidance and welding training.

- You have the option to request our welding engineers to visit your factory for installation and trial.

If you have any business inquiries or product questions, please feel free to contact us.