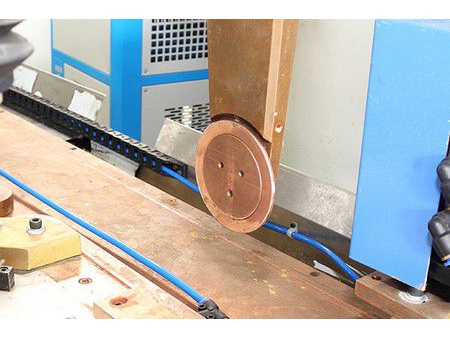

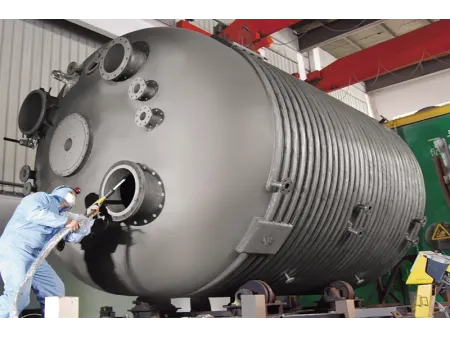

We provide various stainless steel sink welding equipment, including CNC seam welding machine, CNC surface grinding and polishing machine, and manual sink seam welding machine. Our flexibility extends to offering customized solutions, whether it's a fully automatic production line, a semi-automatic production line, or equipment tailored to specific efficiency requirements, according to the preferences and needs of our customers.

Stainless steel kitchen sinks, industrial sinks, hotel sinks, and more