Automotive Industries

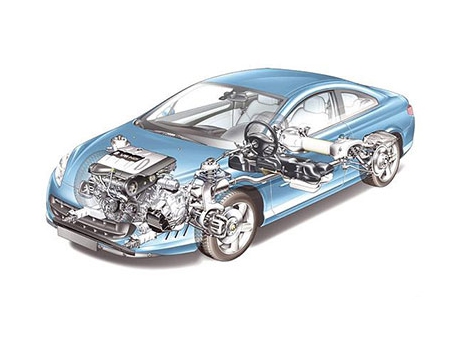

Many precise electrical devices are embedded in the parts of automobiles. These devices feature connections that are realized through large numbers of wires and pipelines. For example, the structures of braking systems and fuel systems are becoming more complicated with the development of technology so that it makes friction between oil cubes or cubes and components and outer impact easier to appear.

In the past, we have used rubber sleeves or springs to protect these pipes and wires but they all have fatal flaws. For example, due to a distance of 0.5mm between the rubber sleeve and oil pipe, once muddy water or saline water infiltrate the cable, corrosion can take place. Although springs can prevent gravel damage, the springs themselves cause friction upon the surface of the oil pipe until it is completely worn down. If the oil pipe features an organic coating like PVC, PVF, springs should not be used.

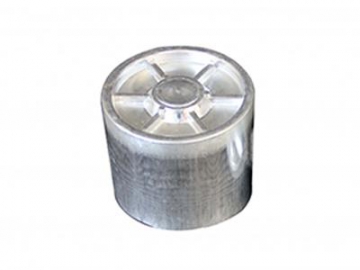

In this situation, heat shrink tubing is the ideal application.

Heat shrink tubing for automobile cables is a kind of dual wall tubing with a hot melt adhesive liner. You just put it in the proper place outside of the oil pipe and heat it. The tubing will shrink into the expected size. The inner hot melt adhesive connects the heat shrink tubing with oil pipe with no void in between. At the same time, the soft material EVA of heat shrink tubing can also buffer the friction between cubes.

This substantially increases the working time of oil pipes to use dual wall pipes to protect the pipes in cars.