DPH400D/Q Triple-Servo/Full-Servo Alu-PVC & Alu-Alu Blister Packaging Machine

Pharmaceutical Packaging Machinery Since 1998

- Alu-PVC: 20–200 cuts/min, 60–1000 blisters per minute

- Alu-Alu: 20–160 cuts/min, 140–640 blisters per minute

- High output, suitable for large-scale production

This Alu-PVC & Alu-Alu blister packaging machine is servo-driven, with a punching frequency of 20–200 cuts/min for Alu-PVC and 20–160 cuts/min for Alu-Alu. Output reaches up to 3.6 million units per shift (5 blisters per stroke, 10 units per blister, 150 cuts/min, 8-hour shift).

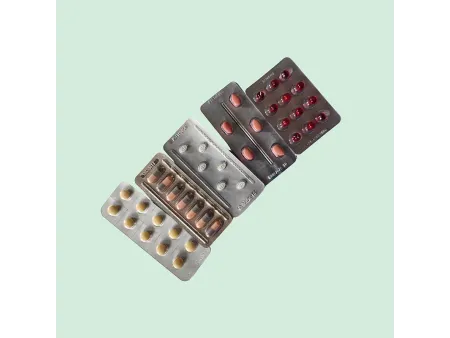

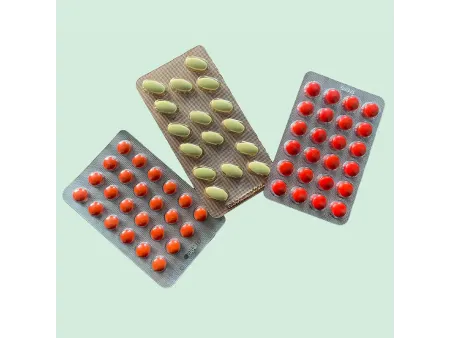

It is suitable for packaging solid dosage forms of various shapes and sizes, including tablets, capsules, soft capsules, and irregular-shaped tablets. Compatible materials include Alu-PVC, PVDC, Alu-Alu, and PET.

The equipment features an enclosed, stainless-steel housing with an aesthetic appearance and complies with GMP requirements for pharmaceutical production. Models can be selected according to different production scales.

Capsules and tablets for industries, including pharmaceuticals, food, and cosmetics.

- The equipment features pressure forming with roller heat sealing, ensuring high packaging efficiency and consistent appearance.

- Equipped with an intelligent servo system and optimized transmission structure, enabling high-speed, stable operation, reduced downtime, and flexible configuration for different production capacities.

- HMI and PLC control, stepless frequency regulation, servo drive; high-speed punching range of 20–160 cuts/min (punching frequency depends on blister length).

- Vision inspection system uses internationally recognized brands for high detection accuracy.

- Multiple alarm functions include material shortage alarm, safety door alarm, temperature alarm, air pressure alarm, and circulating water alarm.

- Internal heating system with automatic temperature control.

- Extended filling platform to improve yield; optional conveyor integration.

- Available cooling methods include circulating water or external tap water connection.

- Waste-free punching, reducing packaging material consumption by approximately 10%.

| Cutting efficiency | Alu-PVC: 20–200 cuts/min Alu-Alu: 20–160 cuts/min |

| Max. forming area | 200 × 430 mm |

| PVC film | 420 × (0.15–0.45) mm |

| PTP | 420 × (0.02–0.03) mm |

| Total power | Full-servo: 18.75 kW Three-servo: 12.75 kW |

| Power supply | 380 V / 50 Hz |

| Dimensions (L*W*H) | 3930 × 1170 × 1860 mm |

| Weight | Full-servo: 3800 kg Triple-servo: 3750 kg |

| Forming method | Alu-PVC: pressure forming Alu-Alu: stamping |

| Sealing method | Roller sealing |

| Noise Level | 75 dB(A) |

| Automatic inspection | Vision inspection |

| Max. forming depth | Alu-PVC: 18 mm Alu-Alu: 12 mm |

| Compressed air consumption | 1.1 m³/h (20 L/min) |

| Compressed air pressure | 0.5–0.7 MPa |

| Cooling water consumption | 0.19 m³/h (3.2 L/min) |

Forming, indexing, heat sealing, punching, feeding, printing, robotic handling, and registration alignment are all servo-driven. All modules operate in coordinated linkage, enabling system-wide shutdown in case of faults while maintaining positional memory during power loss or stoppage. Individual modules can also operate independently for maintenance and adjustment.

Servo drive is applied to forming and indexing, active heat-sealing rollers, and punching feed. Other forming, punching, and printing stations are synchronized through mechanical transmission driven by the main motor, with speed controlled via frequency inverter. Mold changes require only parameter adjustment on the HMI, significantly reducing changeover time.

-

- Web splicing station

-

- Aluminum foil splicing station

-

- Forming station

-

- Rotary feeding station

-

- Universal feeding station / Alu-Alu (irregular tablet) feeding station

-

- Heat sealing station

-

- Punching station

Dalian Hanfang Pharmaceutical focuses on oral solid dosage production, including tablets and capsules, with strict requirements for efficiency and operational stability. Existing equipment could not meet expanded capacity demands.

Huaxin Package customized the DPH400Q high-speed Alu-PVC blister packaging machine, featuring a full-servo drive system and advanced control architecture. The equipment delivers excellent synchronization, lower energy consumption, and enhanced modular coordination, becoming a core asset on Hanfang’s high-capacity production line.

Alu-PVC packaging uses aluminum foil combined with PVC or PVDC formed by positive pressure thermoforming, suitable for general pharmaceuticals. Alu-Alu packaging is formed by cold stamping, offering superior moisture and light protection for sensitive products, improving stability and shelf life.

Yes. With an intelligent servo system and blow forming or stamping processes, the machine supports maximum forming depths of 18 mm (Alu-PVC) and 12 mm (Alu-Alu), accommodating tablets, capsules, soft capsules, and irregular shapes.

A fully enclosed stainless-steel structure, intelligent controls, and high-speed, high-precision motion systems reduce contamination risk and material waste while ensuring stable, compliant production.