Integrated Concrete Batching Plant

HZN-K Series

Pre-wired and pre-plumbed concrete batch plant allowing rapid installation within hours

- Production Capacity 35–75 m³/h

- Plant Configuration Integrated modular structure for fast assembly & transport

The integrated concrete batching plant adopts an integrated structural design. All water, electrical, and pneumatic pipelines are pre-installed at the factory, allowing the plant to be quickly converted into operating status on site and put into service in a short time. When relocation is required, the plant can be rapidly converted into transport mode and is suitable for containerized transportation.

This batching plant features a compact structure, small footprint, and fast installation and dismantling, with stable and reliable performance. It is suitable for producing normal concrete as well as dry, semi-dry, high-performance, and high-strength concrete. Typical applications include short-term construction projects, small concrete job sites, and precast concrete component plants.

Technical Parameters

- Theoretical capacity (m³/h)30

- Mixer modelJN500AH

- Mixer motor power (kW)22

- Charging capacity (L)750

- Discharging capacity (L)500

- Max. aggregate size (mm)≤60

- Hoist motor power (kW)5.5

- Feeding modeSkip hoist

- Screw conveyor modelLSY168/219

- Aggregate batching machine modelHP800

- Aggregate weighing accuracy±2%

- Cement weighing accuracy±1%

- Mineral additive weighing accuracy±1%

- Water weighing accuracy±1%

- Admixture weighing accuracy±1%

- Approx. total power (excluding screw conveyor, kW)52

- Discharge height (m)4

Process Flow

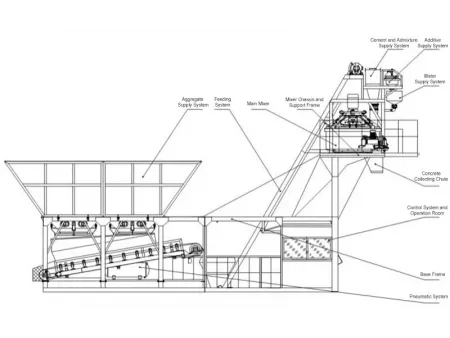

Main Components

The integrated concrete batching plant combines a JN500AH skip-hoist vertical shaft planetary mixer with an HP series aggregate batching machine into a single, cohesive unit.

Integrated Mixer

Built-in JN-AH series skip-hoist planetary mixer. The compact vertical shaft design ensures high-homogeneity mixing within the integrated frame.

Compact Batching

HP series cumulative weighing system directly integrated into the main chassis. Eliminates complex external belt structures for faster setup.

Precision Weighing

Factory-calibrated sensors and pneumatic systems ensure accurate weighing (±1%). Pre-wired and pre-plumbed for immediate use.

Screw Conveyor

Equipped with universal joints for flexible angle adjustment, adapting to various site constraints without heavy modification.

Project Cases

In an export project to Africa, the HZN30K batching plant adopted a containerized transportation solution. One complete plant was shipped using one 40HQ container and one 20GP container. After arrival on site, the plant was rapidly assembled, commissioned, and put into operation, significantly improving on-site construction efficiency.

Established in 1991, Jin Rui is a professional concrete plant manufacturer with over 30 years of industry experience. From stationary concrete plants to integrated concrete plants, our concrete equipment serves various construction projects of high-speed railways, bridges, and airports, delivering reliable concrete production solutions tailored to different construction cycles and site conditions.

Get professional advice for your project - contact our experts today.