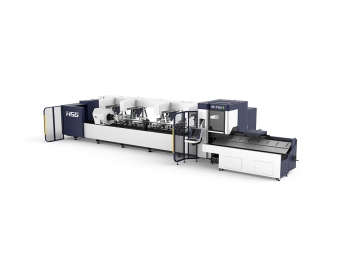

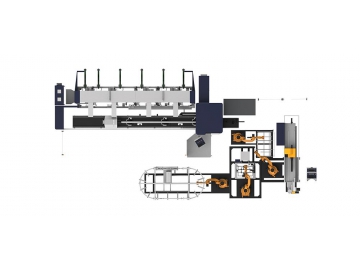

TS65 Tube Processing Line for Automotive Seat Structure

(Including laser tube cutter, robot transfer unit, bender, laser welder, laser cleaner)

TS65 intelligent tube processing line is mainly used for production of metallic frame of automotive seats. The functions of the processing line include feeding, cutting, bending and welding as well as cleaning. The advantage of this processing line is its high degree of automation. That is to say, the whole process just needs one operator because several processes can be finished by the KUKA robot.

The equipment and configuration of the processing line can be substituted by others to be suitable for the various demands of customers. This TS65 intelligent tube processing line can provide functions such as flexible planning, tracking production and inspecting product quality. The tube processing line not only improves equipment work efficiency and product qualification rate, but also reduces manufacturing costs and shorten production cycle.

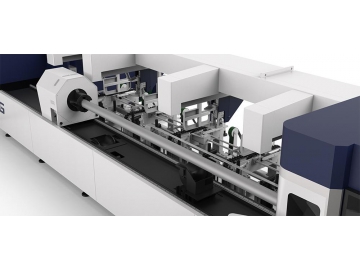

① This tube cutting machine can perform bevel cutting on any tube materials and the cutting angle can reach 45 degrees.

② This laser cutting machine can cut circular tube with a diameter of 20-210mm.

③ This machine can cut square tube with dimensions of 20mm×20mm-150mm×150mm.

Applicable materials:

A variety of metal materials can be cut by this line. These materials include stainless steel, carbon steel, aluminum, brass, copper, galvanized plate and cold-rolled sheet.

Application industry:

The frame of automobile seats

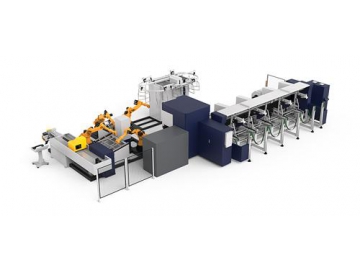

- Material cutting by using laser pipe cutter

- Conveying of pipe after cutting to a transfer station by robotic unit

- Pipe bending by bending unit

- Laser welding

- Laser cleaning

- The pipe material can be divided and arranged automatically by the CNC system to guarantee that the feeding machine can clamp a single pipe from the bundle of pipes and send it to inspection workstation every time. It can accomplish the loading of a bundle of pipes and connect with the pipe cutting process straightly.

- The pneumatic chuck is an integral structure which can center the cutting head automatically. This chuck features high stability.