ZH100/150 Intermittent Motion Vertical Cartoner

Pharmaceutical Packaging Machinery Since 1998

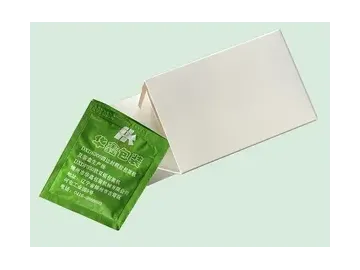

The equipment is a vertical intermittent motion cartoner. It can sequentially complete processes such as product feeding, material transfer, leaflet folding, leaflet insertion, carton erection, product insertion, and carton sealing. The entire cartoning process is fully enclosed.

It is suitable for the automatic cartoning of pharmaceuticals, strip packs, food products, daily chemical products, small hardware items, and similar materials. The main machine adopts a full-servo drive, offering broad applicability.

Automatic cartoning for pharmaceuticals, food, daily chemical products, small hardware items, and related products.

- Variable-frequency speed control with a PLC fully automatic control system; multiple carton specifications can be adjusted within the specified range on the same machine.

- Easy to understand interface, automatically displaying cartoning speed, output count, operating parameters, fault causes, and operation guidance.

- Synchronous completion of leaflet folding (up to four folds), product insertion, and coding; production date and batch number can be printed on cartons, with an optional serial number printing function.

- Equipped with automatic alarm, stop, and rejection functions.

- Can be linked with other equipment to form an integrated production line.

| Model | | |

|---|---|---|

| Production rate | ≤100 cartons/min | ≤150 cartons/min |

| Power supply | 380 V, 50 Hz | 380 V, 50 Hz |

| Installed power | 1.3 kW (including vacuum pump motor) | 1.3 kW (including vacuum pump motor) |

| Carton size (L*W*H) | (65–125) × (45–90) × (12–55) mm | (65–125) × (45–90) × (12–55) mm |

| Leaflet size (L*W*H) | (110–160) × (90–250) mm | (110–160) × (90–250) mm |

| Compressed air pressure | 0.5–0.7 Mpa | 0.5–0.7 MPa |

| Noise level | 75 dB(A) | 75 dB(A) |

| Dimensions (L*W*H) | 1085 × 1165 × 1475 mm | 1085 × 1165 × 1475 mm |

| Weight | 1200 kg | 1200 kg |

Qinghai Tibetan Hospital selected the ZH150 cartoning machine to match its large-scale production needs. The production line requires frequent changeovers for multiple product types. With convenient parameter adjustment, the ZH150 enables fast switching between different carton specifications, ensuring production continuity and stability.

Production efficiency can be improved by increasing operating speed and precision, using high-quality consumables, and performing regular maintenance to ensure stable, efficient operation.

Common issues include mechanical transmission faults and carton or paper waste. This equipment adopts a full-servo modular design with toothed-belt transmission and no chains, making maintenance easier and fault resolution faster. The integrated intelligent inspection system monitors operating status in real time, helping to identify and resolve issues promptly and improve overall reliability.

Yes. Professional installation, commissioning, and operator training services are provided to ensure the equipment can be quickly and smoothly put into production after delivery.