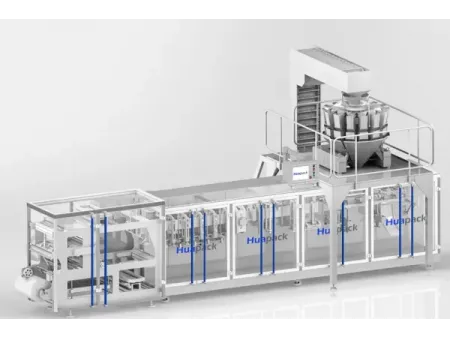

Zipper Stand-Up Pouch HFFS Packaging Machine, 1-Nozzle Filling

Horizontal form fill seal machine

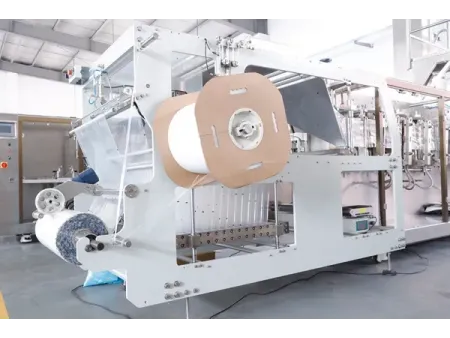

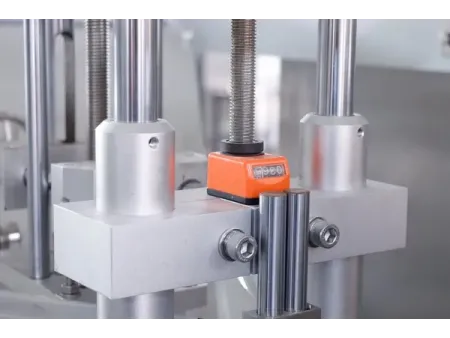

Rollstock zipper stand-up pouch packaging machines are used to produce self-standing pouches with a reclosable zipper through a fully automatic process. Made with a main frame and moving parts in 304 stainless steel to ensure easy cleaning, the sipper pouch packaging system uses servo control to handle film unwinding, bottom-gusset forming, accurate filling, and sealing, while precisely positioning and heat-welding the zipper strip onto the pouch opening, delivering finished, resealable stand-up packs in a stable and continuous high-speed operation.

| Performance features | Rollstock zipper stand-up pouch parameters | | | | |

| Pouch parameters | Min. pouch size | 75x100mm | 90×110mm | 110×150mm | 120x160mm |

| Max. pouch size | 130x225mm | 180×225mm | 240×320mm | 280x300mm | |

| Filling volume (max.) | 800ml | 1000ml | 2000ml | 3000ml | |

| Packaging speed (pouches/min) | ≤60 | ≤60 | ≤60 | ≤60 | |

| Machine specifications | Machine dimensions (L × W × H) | 6000mmx1200mmx1800mm | 6700mm×1200mm×1800mm | 7500mm×1200mm×1800mm | 8000mmx1200mmx1800mm |

| Operating conditions | Machine weight | 1800kg | 2100kg | 2400kg | 3400kg |

| Air consumption | 400L/min | 400L/min | 400L/min | 400L/min | |

| Main drive power | 9Kw | 9Kw | 9.5Kw | 9.5kw |

Zipper opening

Pouch hole punching

- Sombrero hole (butterfly hole)

- Round hole

- Special-shape punching

- Arc hole / Curved slot hole

- Euro hole

Coding options

- Hot stamp coding

- Inkjet printing

- Laser marking

Sealing patterns

- Grid pattern

- Dotted pattern

- Plain/flat pattern

- Vertical rib pattern

In 2024, a well-known pet food producer in Russia chose the 240SZ rollstock zipper stand-up pouch packaging machine for packing their products. Since the pouch packaging equipment was put into operation, it has been running smoothly with no after-sales issues, and the customer has given very positive feedback on its stability and overall performance.