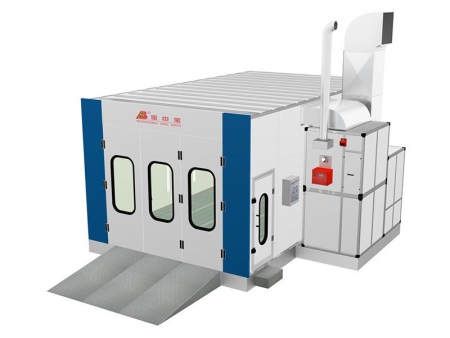

Mobile Container Spray Paint Booth

When you have to paint or coat 'On Site', profitability demands that you maximize every aspect of transportability to stay competitive.

THIS is the solution that you're looking for!

BZB-BF mobile container spray booth is newly developed based on the fixed automotive spray booth by Jingzhongjing. It’s constructed with shipping container as the spray room. Designed with retractable side walls on the front, the mobile spray booth features outstanding overall sealing performance due to the superior sealing device around the booth. Two sides of the spray booth come with telescopic guide rails to support the retractable walls with casters. In addition, the control cabinet is equipped on the back of the paint booth, and the space for installing air compressor is reserved. This integrated structure greatly facilitates transportation. It is worth mentioning that the retractable design on two sides enlarges the work area, and reduces transportation costs. Adjustable cabin work area and mobility are easily achieved by this container spray booth.

The container spray booth is available with various specifications, and also can be customized upon request. Its installation is already completed before delivering, and there is no custom operational requirement. With an integrated design, it can be moved to any job site in a convenient manner. As an innovative mobile spray paint booth, this finishing equipment is widely used for surface preparation, coating, painting, and finishing applications. Known for its rugged construction, the container spray booth features good resistance to harsh working conditions, which is a great mobile finishing solution.

- Spray Area Dimension 7100/6654(L) * 4000(W) * 2400(H)mm(extended)

- Outer Dimension10800(L) * 2438(W) * 3400(H)mm(retracted)

- Outer Dimension10800(L) * 4202(W) * 3400(H)mm(extended)

- Power 415V, 3 Phase, 50Hz

- Total power 16.5kW

- Air inlet Chamber

The intake filter is added to remove particulates from the incoming air, two layer of filter is applied, top layer adopts cotton structure, bottom layer adopts grid structure.

Air Supply and Exhaust System- The system consists of the white rock wool-coated profiles and movable board (notes: the filter should be changed and checked regularly)

- Air supply: centrifugal fans DDF-7.5KW, driving the ABB motor directly, 415V/50HZ/3PH

- Air exhaust: TAE-500-7.5KW, driving the ABB motor by belt,415V/50HZ/3PH

- Generator: rear mounted

- Basement

- Two floor galvanized gratings, and three floor checkered plates(sprayed)

- The bottom is sealed, welded with the platform bracket

- With 2 pieces of slope for loading(sprayed), 2000×900(L×W)

- Use constant-temperature checkered plates for back floor

- Two floor galvanized gratings, and three floor checkered plates(sprayed)

- Outer Frame

Welding structure of square pipe, I-beam, channel steel, bending parts, corrugated plate, etc.

- Purification System

- Top layer filter: Flame retardant 600G

- Floor layer filter: made from fiber glass(green)

- Air outlet filter: M-type filter cotton, no filter cover

- Top layer filter: Flame retardant 600G

- Heating System

The G20 type burner gives a maximum heating value of 180,000kcal/kg with SUS304 high-quality stainless steel, with 4 exhaust ducts and rain cap.

-

- Chamber System

- Composed of 2 pieces of 50mm thick flame-resistant EPS insulation board(2200×2500mm) and 6mm tempered glass observation window(1150×550mm)

-

- Blasting safety Chamber

- Composed of 50mm thick EPS wall panel on each side, with pressure lock and observation window.

-

- Maintenance Chamber

- Composed of 2 pieces of 50mm EPS insulation wallboard(2200×2600mm), with pressure lock and vents

-

- Air Supply and Exhaust Duct

- With enough transfer duct 2 additional air inlets rain cap 4 air exhaust ducts gravity damper

-

- Sealing

- 1. Welded with outer two-sided corrugated plate and EPS50mm thick flame-resistant insulation board

2. Single-sided corrugated plate is used in the non-ventilated part

-

- Telescopic Guide Rail

- Can be operated manually by 2 workers

-

- Illumination System

- Australian-Standard with 8 side lights

-

- Electric Control System

- Australian-Standard electric control system, with star-delta starter and pressure gauge