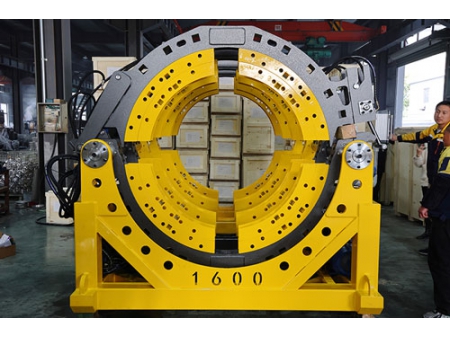

Hydraulic Butt Fusion Machine, WP1600AH

1000-1600mm Plastic Pipe Welding Machine with Manual Locking

The butt fusion machine is ideally used for butt welding of HDPE, PP, PVDF, MPP pipes and fittings.

- Model: WP1600AH

- Welding range: 1000-1600 mm

- Standard reducers: 1200-1400-1600 mm

- Optional reducers: 1000 mm

- Power supply: 380V/50Hz, 3PH

- Total power: 61.5 kW

- Heating plate: 50 kW

- Planing tool: 7.5 kW

- Hydraulic station: 7.5 kW

- Pressure adjusting range: 0-16 MPa

- Max Temperature of heating plate: 270ºC

- Temperature Deviation: ±10ºC

- The machine frame is made by using laser-cut steel plate which has undergone high quality welding. This ensures high stability, high dimensional precision, and beautiful appearance.

- The hydraulic station integrates the hydraulic and electric control systems with an integrated control panel, reducing operation and providing reliable and stable performance.

- The butt fusion machine is equipped with an external hydraulic cylinder that reduces maintenance time. In addition, the cylinder is designed with graphite copper sleeves which provide a smooth contact surface of different parts and reduce the friction force

- The butt welding machine can be optionally equipped with 3 or 4 clamps, making it suitable for fusing solid wall pipes and corrugated pipes.

- Hydraulically-driven locking and opening/closing is optional, which increases the speed of pipe installation by 60%.

- Data logging device is optional

-

-

The rack structure has high overall integrity and is not easily deformed under heavy loads.

-

-

This machine adopts laser cutting technology. Compared to traditional welding machines, the weight of this machine’s parts is greatly reduced while maintaining high precision and strength, effectively reducing the workload during construction.

-

-

The hydraulic system and the electrical control system are combined together in the hydraulic station, allowing for better coordination and control between the two systems as well as providing reliable and stable performance with convenient operation.

-

-

Equipped with a heavy-duty transmission chain and a self-tightening system, the machine has improved transmission efficiency, providing stable performance with reduced noise.

The machine features a high-quality motor made with copper wiring and a thick cutting disc made of smooth and flat aluminum that is not prone to cracking. Additionally, the cutting blade is made of durable high-strength steel, ensuring a long lifespan and reducing the need for frequent replacements.

-

-

The surface of the heating plate is polished to be flat, smooth, and free of roughness. High-quality heating resistance wires are used to make heating quickly and evenly. The heating element is applied with superior DuPont or Daikin coating.