Butt Welding Machine

Request a Quote

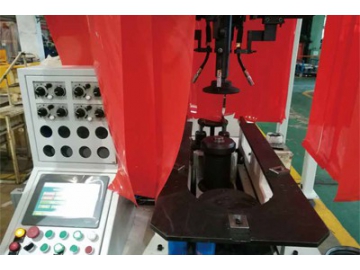

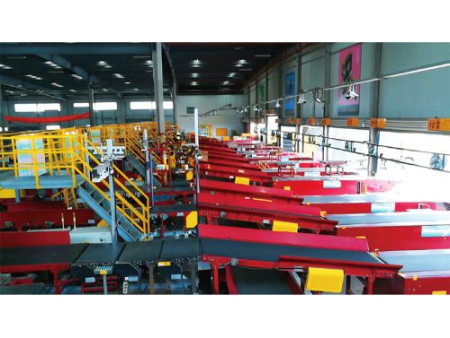

Butt welding machines are an essential part in a wheel rim production line, using a hydraulic drive for clamping and welding of workpieces. The welding parameters are set on a touch screen, and this equipment features a high degree of automation, reliable operation system, and easy adjustment. The butt welder consists of the welding machine, electrical system, and hydraulic system.

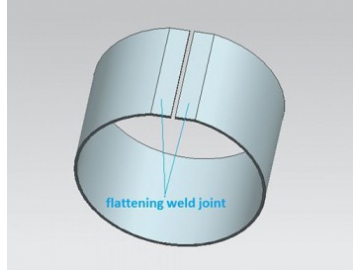

Process drawings Flattening weld joint

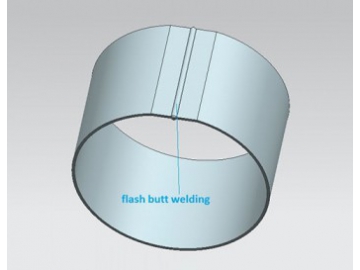

Flattening weld joint Flash butt welding

Flash butt welding

- There is a welding slag scraper on the welding jaw to automatically remove slags and facilitate usage.

- The welding current is multi-stage adjustable, applicable to welding rims in different specs.

- A high-quality copper electrode features an outstanding electrical conductivity, offering a high welding quality and a rejection rate within 0.5%.

- The hydraulic system is designed with a compact structure to save floor space. A filth blockage resistant hydraulic pump and servo valve is used, giving the hydraulic system an excellent resistance to dust pollution and low requirements for dustless production environments to save initial investment costs.

- Combined manual control and automatic control is easy to operate.

- The integrated control circuit features a convenient installation and maintenance.

- The overall frame design ensures a high strength and ensures the welding accuracy.

- An automatic welding slag conveyor is an optional accessory to remove slag at the bottom of the welder.

| No. | Items | Data | |||

| 1 | Model | UNB2-630 | UNB2-800 | UNB2-1000 | UNB2-1600 |

| 2 | Main circuit rated input voltage | AC 380V/1Phase | AC 380V/1Phase | AC 380V/1Phase | AC 380V/1Phase |

| 3 | Control circuit rated input voltage | AC 380V/3Phase/50Hz | AC 380V/3Phase/50Hz | AC 380V/3Phase/50Hz | AC 380V/3Phase/50Hz |

| 4 | Secondary voltage | 6.55V to 11.8V | 8.8V to 14.6V | 8.8V to 14.6V | 8.8Vto19.6V |

| 5 | Voltage of solenoid valve | DC 24V | DC 24V | DC 24V | DC 24V |

| YV11, YV12 @AC 220V | YV11, YV12 @AC 220V | YV11, YV12 @AC 220V | YV11, YV12 @AC 220V | ||

| 6 | Total power input | 630kVA | 825kVA | 1050kVA | 1610kVA |

| 7 | Rated power at 50% transformer utilization factor | 600kVA | 800kVA | 1000kVA | 1600kVA |

| 8 | Max. upsetting force | 280kN | 320kN | 320kN | 400kN |

| 9 | Max. clamping force | 650kN | 650kN | 650kN | 650kN |

| 10 | Max. welding cross section area | 3200mm 2 | 3500mm 2 | 4000mm 2 | 6000mm 2 |

| 11 | Max. width of rim band | 350mm | 410mm | 500mm | 800mm |

| 12 | Max. thickness of rim band | 4.5mm | 8mm | 10mm | 13mm |

| 13 | Min. diameter of rim welded | 250mm | 400mm | 400mm | 500mm |

| 14 | Cooling water flow rate | 4500liters/hour | 4500L /H | 5000L /H | 6000L /H |

| 15 | Pressure of cooling water | 0.2~0.4MPa | 0.2~0.4MPa | 0.2~0.4MPa | 0.2~0.4MPa |

| 16 | Temperature of cooling water | No more than 20℃ | No more than 20℃ | No more than 20℃ | No more than 20℃ |

| 17 | Rejection rate | No more than 0.5% | No more than 0.5% | No more than 0.5% | No more than 0.5% |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos