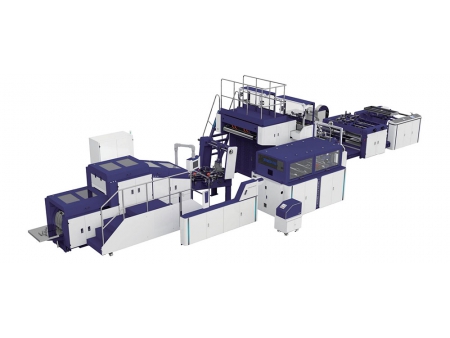

Automatic 4 Lines Cold Cutting Bag Making Machine

Request a Quote

View All: http://plastic-bagmachines.com/1-1-2-automatic-4-lines-cold-cutting-bag-making-machine.html

Suitable for making biodegradable plastic T-shirt shopping bags/flat garbage bags

Video

This automatic 4 lines cold cutting bag making machine can be used to produce biodegradable vest bags and flat-opening bags. At its heart is a Taiwan frequency conversion motor, providing the ability to save energy and adjust the speed in a more flexible manner.

The unwinder with Taiwan design offers the same speed as the main machine, making it highly efficient. All the electric components are from world's well-known brands to ensure the long service life of the plastic bag machine, and the high level of automation contributes in reducing labor intensity.

Technical Parameters

| Model | RG-DL800C | RG-DL1000C | RG-DL1200C |

| Sealing and cutting width (mm) | 750*2 360*4 | 950*2 460*4 | 1150*2 560*4 |

| Sealing and cutting length (mm) | 1500 | 1500 | 1500 |

| Bag making speed (pcs/min) | 240-480 | 240-480 | 240-480 |

| Power of motor (kW) | 1.5 | 1.5 | 2.2 |

| Weight (kg) | 1300 | 1500 | 1700 |

| Dimension (m) | 4.8*1.4*1.9 | 4.8*1.6*1.9 | 4.8*1.8*1.9 |

Application

This automatic 4 lines cold cutting bag making machine is typically used to make T-shirt shopping bags for supermarkets and retail stores, as well as flat bags for garbage disposal.

Details

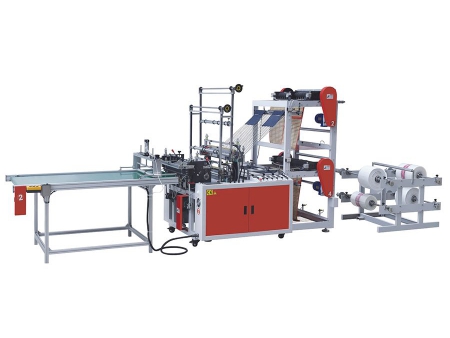

- Unwinder 370 W, A/C motor, inverter control

- Photosensor High quality photosensor for precisely controlling the unwinding film rolls

- Sealing Unit Sealing knife is made of high strength casting copper that has been subjected to heat treatment, ensuring it won't warp from heat

- Air Cooling System Controlled by Taiwan AirTAC electric valve

Air cooling method secures an increased sealing strength, without stretching - Cutting Unit With the use of a spring-based cutting design, the cutting unit is made easier for user to operate

The longevity of the cutting knife is increased thanks to the use of SK-II alloy steel - Component Taiwan FOTEK solid state relay

Omron temperature controller

Schneider electric components Panasonic photocell

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos