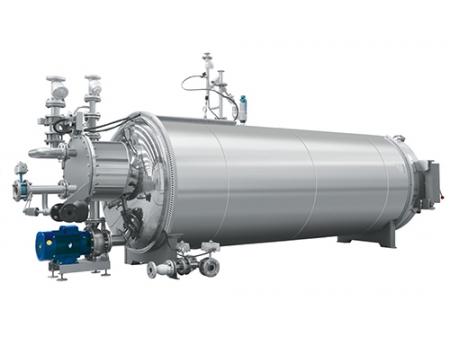

Water Spray Retort without Preheat Tank

If the customer's product has an initial temperature near room temperature, a water spray retort without a preheating tank is recommended. This type of retort requires no additional tank, thus providing the added benefit of lower transportation costs and saving on sea freight due to its reduced size.

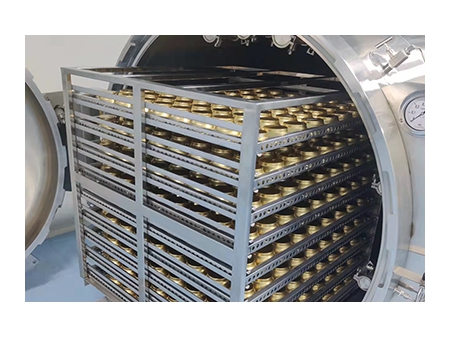

Common products that can be sterilized include soft packaging, tinplate bowls, glass bottles of bird's nest, and boxed paper products.

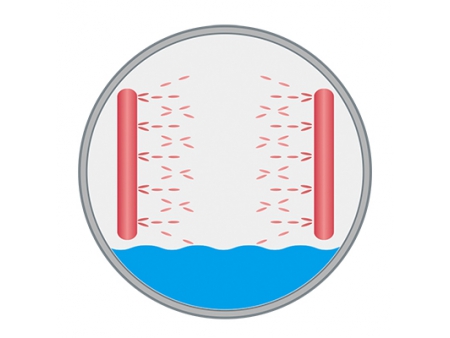

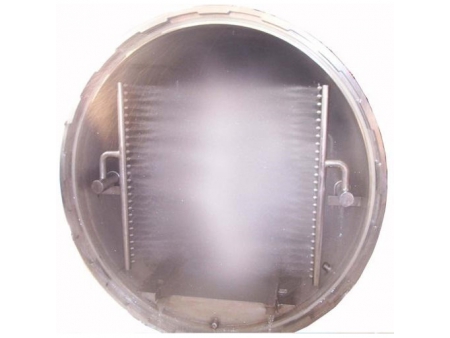

This water spray retort is capable of top spraying, side spraying, and top two sides spraying. Of these, top two sides spray has been the most popular among previous sales cases due to its higher sterilization effect and high customer acceptance. Equipment customization is also offered based on customer product packaging, size, and output per hour requirements.

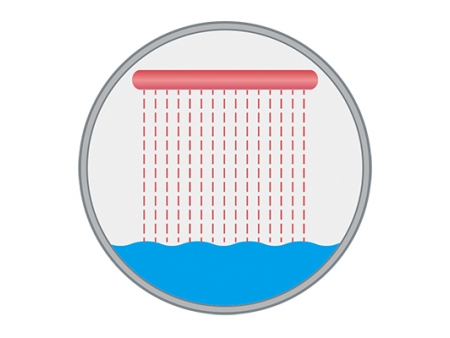

Top Two Sides Spray

Top Spray

Side Spray

| Model | Dimension (mm) | Retort wall thickness (mm) | Max. working pressure (Mpa) | Max. working temperature (℃) | Approx. retort weight (kg) | Approx. operating weight (kg) | Power (kW) | Voltage (V) | ||||

| Capacity (m3) | ||||||||||||

| L | W | H | Top spray (water cascading) | Side spray / combined top and side spray | ||||||||

PLJ09-2 | 3080 | 1400 | 1400 | 4 | 0.3 | 130 | 1020 | 1500 | 1.33 | 3 | 4 | 380 |

PLJ10-1 | 2300 | 1500 | 1650 | 4 | 0.3 | 130 | 1000 | 1300 | 0.95 | 1.5 | 2.2 | 380 |

PLJ10-2 | 3100 | 1470 | 1650 | 4 | 0.3 | 130 | 1300 | 1800 | 1.65 | 3 | 5.5 | 380 |

PLJ12-2 | 3400 | 1700 | 1850 | 5 | 0.3 | 130 | 1380 | 2100 | 2.43 | 4 | 7.5 | 380 |

PLJ12-3 | 4300 | 1700 | 1850 | 5 | 0.3 | 130 | 1630 | 2750 | 3.46 | 4 | 7.5 | 380 |

PLJ12-4 | 5200 | 1700 | 1850 | 5 | 0.3 | 130 | 1860 | 3300 | 4.46 | 5.5 | 7.5 | 380 |

PLJ13-4 | 4600 | 1800 | 2100 | 6 | 0.3 | 130 | 2300 | 4000 | 5.81 | 7.5 | 11 | 380 |

PLJ14-4 | 5500 | 1900 | 2200 | 6 | 0.3 | 130 | 2500 | 4460 | 6.77 | 7.5 | 11 | 380 |

PLJ15-4 | 5800 | 2000 | 2400 | 6 | 0.3 | 130 | 2900 | 5900 | 7.82 | 11 | 15 | 380 |

PLJ15-5 | 6850 | 2000 | 2400 | 6 | 0.3 | 130 | 3250 | 6000 | 9.59 | 11 | 15 | 380 |

PLJ15-6 | 7700 | 2000 | 2400 | 6 | 0.3 | 130 | 3500 | 6700 | 11.35 | 11 | 15 | 380 |

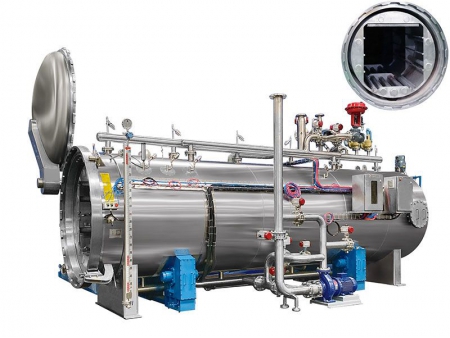

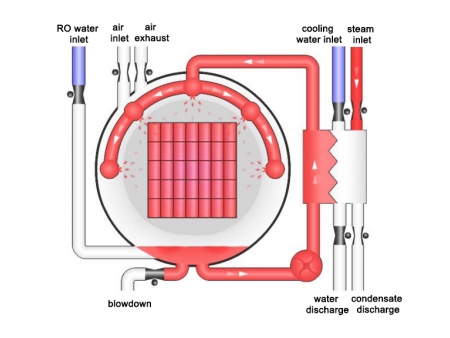

- Water inlet: To ensure sterilization, inlet a precise amount of sterilized water into the base of the water spray retort.

- Sterilization: The circulating pump in the closed system constantly circulates sterilizing water. This water is dispersed in the form of a mist and sprayed across the surface of the sterilizer. Steam enters the heat exchanger and raises the temperature of the circulated water until it reaches a controlled temperature. A pressurizing valve and an exhaust valve are used to regulate the pressure inside the retort and ensure it is kept within a specified range.

- Cooling down: The flow of steam is interrupted in the heat exchanger, and cooled water is circulated through it to reduce the temperature to the predetermined level. The temperature continues to drop until the set temperature is reached.

- Blowdown: The blowdown valve is used to discharge any remaining sterilization water while the exhaust valve is used to reduce the pressure inside the retort.

Control panel

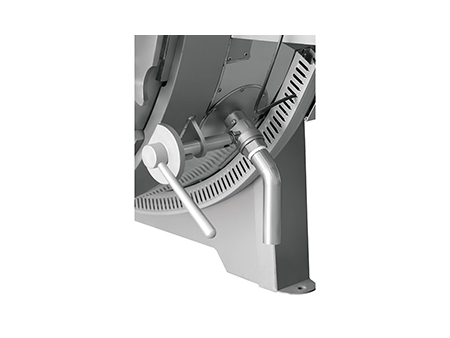

Manual interlock

-

Heat exchanger

-

Pressure gauge

-

Solenoid valve

-

Filter

This retort sterilization equipment provides three distinct sterilization methods to cater to various retort food processing needs:

- Top spray retort

- Top two sides spray retort

- Side spray retort