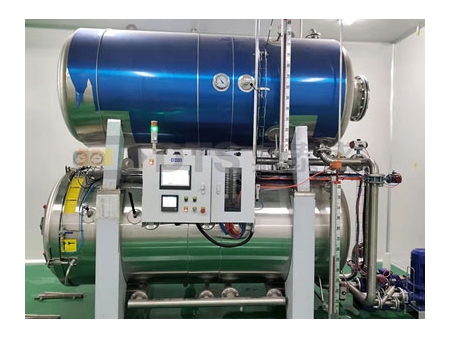

Water Immersion Retort

Water Immersion Retort

Water immersion retort adopts hot water that is preheated to the desired temperature in the top storage vessel before entering the retort chamber, thus resulting in an improved heating efficiency which translates to the faster sterilization process. When the sterilization is completed, the hot water used for sterilizing will be recycled back into hot water tank for the purpose of energy saving.

The sterilization process is automatically performed following the recipe set in the micro processing controller PLC. The uniformity of temperature and pressure distribution inside the retort is within ±0.5℃ and ± 0.05bar, respectively. The buoyancy of water at high temperatures helps to protect product, even under high rotational speeds. The water immersion retort is ideally suitable to process flexible containers and high viscosity large-volume packaged products, enabling the products to be evenly heated.

- Package type: plastic bottles/bowls/cups, large-volume flexible pouches, sausage casings

- Food type: dairy products, meat, fish, seafood, ready meals and soups

- Uniform water flow distribution

- By switching the water flow direction in the retort vessel, uniform water flow is reached at any position in vertical and horizontal directions. This offers even water distribution to the center of every sterilization tray, thus achieving uniform and perfect sterilization effect.

- High temperature and short time sterilization

- Water immersion retort provides reduced come-up times by introducing preheated water from the top storage tank. So, it takes less time to reach the desired sterilization temperature.

| Model | Diameter (mm) | Cylinder Length (mm) | Volumn (m³) | Overall Length (mm) | Overall Width (mm) | Overall Height (mm) | Basket Size (L×W×H/mm) | Designed Temperature (℃) | Tested Pressure (Mpa) | Designed Pressure (Mpa) |

| | 1000 | 1600 | 1.49 | 3200 | 1700 | 2900 | 758×650×621 | 147 | 0.44 | 0.35 |

| | 1000 | 2400 | 2.12 | 4000 | 1700 | 2900 | 758×650×621 | |||

| | 1200 | 2700 | 3.45 | 4500 | 2100 | 3350 | 860×800×775 | |||

| | 1200 | 3600 | 4.47 | 5400 | 2100 | 3350 | 860×800×775 | |||

| | 1200 | 4500 | 5.49 | 6300 | 2100 | 3350 | 860×800×775 | |||

| | 1400 | 3000 | 5.24 | 5200 | 2500 | 3900 | 920×920×915 | |||

| | 1400 | 3900 | 6.62 | 6050 | 2500 | 3900 | 920×920×915 | |||

| | 1500 | 4250 | 8.26 | 6650 | 2600 | 4450 | 1000×1000×975 | |||

| | 1500 | 5300 | 10.12 | 7700 | 2600 | 4450 | 1000×1000×975 |

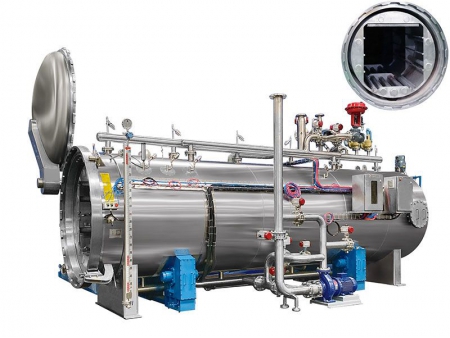

First, send the product into the sterilization retort in a basket and then close the door, which is secured by a triple safety interlock. The whole sterilization process is then automated and controlled by PLC.

Next, high-temperature water from the hot water tank is injected into the sterilization retort. Once mixed with the product, the resulting mixture is continuously circulated through a high-capacity water pump and a network of expertly placed water distribution pipes. This ensures that the heat is evenly distributed throughout the product as it flows. To further elevate the temperature and achieve proper sterilization, the mixture is then passed through a water vapor mixer and infused with steam.

The sterilization retort features a liquid flow switching device that allows for the direction of water flow in the process tank to be switched, achieving uniform water flow at any position in both vertical and horizontal directions. This results in an excellent distribution of heat and ensures that the product is uniformly sterilized.

The pressure inside the sterilization retort is set by program-controlled automatic valves that allow compressed air flowing into or out of the resort. Since the technique adopted is water immersion, the pressure can be freely adjusted according to the package of sterilized product, and will not be affected by temperature. This would make the sterilization equipment more widely applicable in three-piece cans, two-piece cans, flexible packaging bags, glass bottles, plastic packaging, etc. Moreover, the cooling water can be recycled to the tank so as to save the heat.

Finally, wait for the alarm signal for completing the sterilization. And the door can then be opened and the product can be unloaded, after which the equipment is ready to sterilize the next batch of products.

The temperature distribution inside the retort has a uniformity of /- 0.5℃. The pressure is controlled at 0.05 bar.