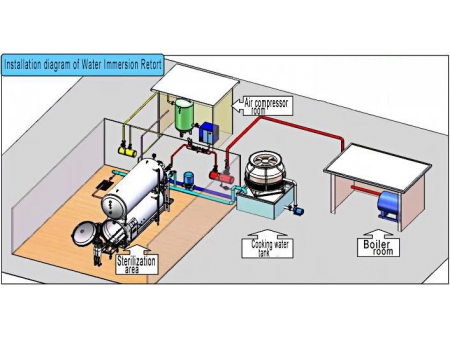

Water Immersion Retort

Water immersion retort is a food sterilization autoclave used to sterilize packaging containers through hot water immersion method. The water is heated to the preset temperature in the top storage vessel and then transferred into the retort chamber, providing fast heat penetration and reducing processing time. The water immersion sterilization of products is continuously performed by constant circulation of the sterilizing water.

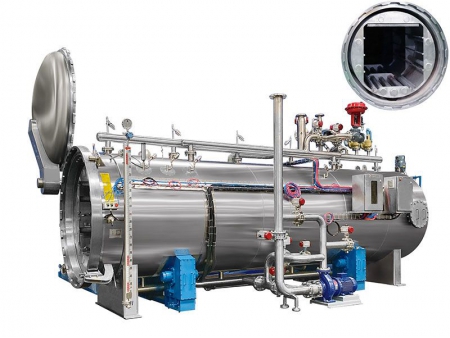

Improved on the basis of previous generation, this newly developed water immersion retort is characterized by forced circulation of hot water, rapid circulation speed and uniform temperature distribution therefore guaranteeing the high consistency of sterilization effect.

Water immersion retort is suitable for large-sized flexible pouches, plastic bottles, plastic bowls, plastic cups, heat-resistant packaging, etc.

This autoclave can be applied to food products that are not sensitive to temperature, such as sauce and braised meats.

The deliberate design of piping system paired with high-flow low-head pump helps reduce water consumption and heat losses thanks to its shortened length and less turns.

Water immersion retort is an ideal solution to retain more original color, flavor and nutrients of food due to its fast sterilization process and high production efficiency.

| Model | Dimension (mm) | Retort wall thickness (mm) | Max. working pressure (Mpa) | Max. working temperature (°C) | Approx. retort weight (kg) | Approx. operating weight (kg) | Capacity (m3) | Power (kW) | Voltage (V) | ||

| L | W | H | |||||||||

CT10-2 | 3600 | 1600 | 2650 | 4 | 0.3 | 130 | 1850 | 5100 | 1.65 | 8.5 | 380 |

CT12-2 | 3600 | 1800 | 3050 | 5 | 0.3 | 130 | 2200 | 6900 | 2.43 | 8.5 | 380 |

CT12-4 | 5400 | 1800 | 3050 | 5 | 0.3 | 130 | 3000 | 11000 | 4.46 | 16.5 | 380 |

CT13-4 | 5700 | 1900 | 3250 | 6 | 0.3 | 130 | 3350 | 14800 | 5.81 | 29.5 | 380 |

CT14-4 | 5800 | 2000 | 3450 | 6 | 0.3 | 130 | 3700 | 17000 | 6.77 | 29.5 | 380 |

CT15-4 | 5900 | 2200 | 3800 | 6 | 0.3 | 130 | 5200 | 20200 | 7.82 | 29.5 | 380 |

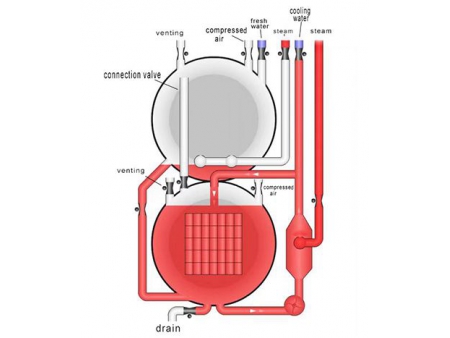

- Preheating: The process starts by filling the upper tank with water and heating it to the desired temperature.

- Inlet: Once the water in the upper tank has reached the desired temperature, it is transferred into the retort.

- Sterilization: The sterilizer operates as a closed system. A circulating pump continuously circulates the water within the water immersion retort. As steam enters the circulating pipe, it heats the water, raising its temperature to the desired level for sterilization. The pressure inside the retort is controlled through the use of a pressurizing valve and vent valve, ensuring it remains within the specified range.

- Water Reuse: After the sterilization process, the sterilization water is pumped back into the upper tank.

- Cooling: Cold water is introduced into the sterilization retort to gradually decrease the temperature of the system. The cooling process continues until the temperature reaches a predetermined level.

- Water Drainage: The circulation water pump is used to drain the cooling water from the system. Additionally, an exhaust valve is opened to release any pressure that may have built up inside the retort during the cooling process.

- Adopting advanced water-steam mixer, ensuring low noise level and high efficiency;

- Improved circulation system, providing better heat distribution;

- Constructed with high-grade material and configured with reliable parts from world's trusted supplier such as Siemens and Mitsubishi, guaranteeing high quality of retort;

- After sterilization process, sterilizing water is pumped back to the top storage vessel, significantly lowering water and steam consumption;

- Load bearing structure carries the weight of top vessel and transfers the load to the floor, without affecting the vessel body and door flange;

- Exterior pipes are connected to the back side of the retort, providing superior look while assisting users in maximizing the utilization rate of workshop;