Sectional Warper, JT231

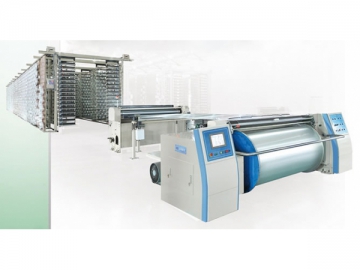

Sectional Warping Machine | Textile Machine | Warping Speed 20-800m/min, Max. Working Width 3600mm

This series sectional warper is divided into two types, namely JT231F type and JT231C type. The beaming unit of the former warping machine is in stationary design, characterized by compact structure and easy installation. It can be provided with two warping units to reduce cost of investment. The JT231C warper is specially designed for fine wool fabrics. It comes with a state of the art Benninger warping creel.

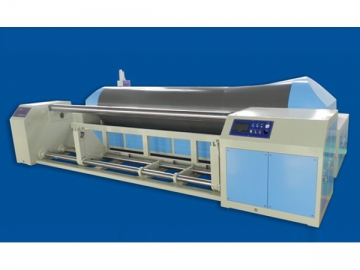

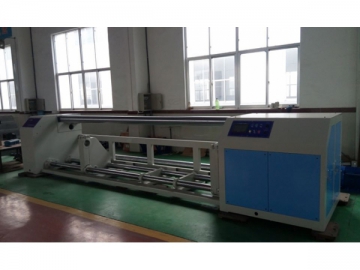

Beaming unit

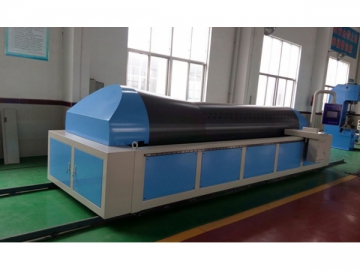

Beaming unit Warping Drum

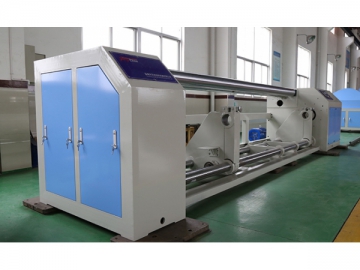

Warping Drum Touch screen of beaming unit

Touch screen of beaming unit Touch screen of warping drum

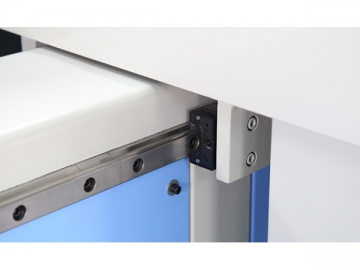

Touch screen of warping drum Linear guide rail

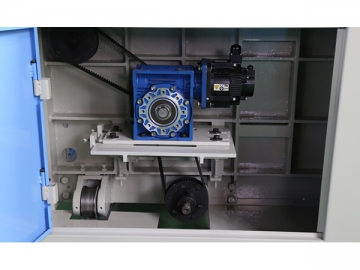

Linear guide rail Servo system

Servo systemProduct Details of the Sectional Warper

1. Integral Structure

This sectional warping system features its main machine integrally installed on a ground rail, and driven by servo motor. The beaming unit, leasing reed and warping creel are stationary.

2. Warping Drum and Drive

The warping drum with fixed cone of different angle is made of high quality steel with high precision dynamic balance. It is driven by AC variable frequency motor, realizing constant linear velocity. Speed can be preset through the touch screen.

3. Yarn Band Section-Carrier Trolley

Section carrier trolley driven by AC digital servo system directly receives the digital signal from the sensor on warping drum, ensuring synchronous working with quick response and high precision. In addition, servo drive system can effectively avoid machine shake and reduce installation difficulty.

4. Equidistant Winding

This series sectional warper is designed with a step motor driving system to control the movement of beamer. During the course of warping, the beamer moves back uniformly and the yarn guide roller maintains a certain distance with the yarn, keeping even yarn tension.

5. Spacing Reed

Front spacing reed is installed on the guide rail with a sliding block, and is automatically controlled by air cylinder for its position. In working, the reed stays close to the guide roller, reducing band spread. When machine stops, it will back off.

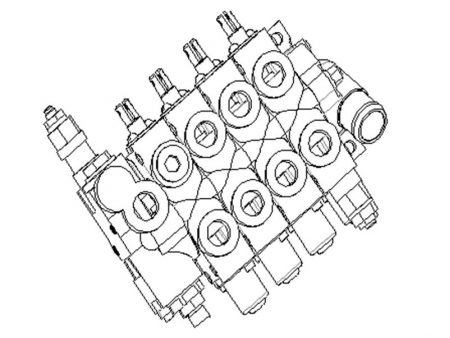

6. Braking Device

This textile machine applies a disc brake that is controlled using pneumatic and hydraulic pressurization technology, ensuring sensitive braking (braking length is less than 3m at a machine speed of 400m/min). This ensures that yarn breakage will not rolled into the drum at normal starting up, thus improving working efficiency and quality.

7. Beaming Tension

Our section warper features beaming tension automatic control, maintaining constant tension during whole beaming course.

8. Automatic Measuring System for Displacement

The warping machine is designed with a servo driven measuring system. Controlled by computer, it can automatically measure the real displacement of yarns.

9. Leasing Reed

The automatic warping system is equipped with an automatic leasing reed with three-point fix method, realizing auto leasing of yarns.

10. Complete Auxiliary Devices

Waxing device, anti-static device and press roller device are optional.

11. Electrical Control System and Key Accessories

Electrical and pneumatic components of the sectional warper are all famous brand products, ensuring reliable quality.

12. Fault Detection System

The sectional warping machine comes with a complete fault detection system which can detect its faults including misoperation, limit protection, running condition of computer, etc. It can display the information detected for convenient maintenance.

13. Production Information Management System

It can automatically work out daily output, monthly output, and other production information. It can also print the information out for scientific workshop management.

14. Creel

Our sectional warper is equipped with various types of creel. Number of spindle, spindle pitch, tensioner, etc. can be selected as per customers' requirements.

Main Performance Index

Warping speed: 20-800m/min, continuously variable

Beaming speed: 5-100 m/min, continuously variable

Speed accuracy: ≤ ±2%

Warping tension (band tension): <6000N (at 60m/min)

Warping tension accuracy: ≤ ±2%

Beaming tension accuracy: ≤ ±2%

Single yarn tension accuracy: ≤ ±2%

Thread traveling speed: 0.001-9.999mm/r, continuously variable

Thread traveling accuracy: ≤ ±2%

Band width range: 0.1-350mm

Band positioning accuracy: ≤0.1m

Maximum band number: 999

Braking distance: <3m (at 400m/min)

Breakage auto-stop rate: 100%

Main Parameters of the Sectional Warper

Working width: 2300 (2600, 2800, 3000, 3400,3600) mm

Beam diameter: 800 (1000, 1250) mm

Drum diameter: 1000mm

Cone ratio: 1:8, 1:5

Creel spindle number: 640 (Customizable)

Creel spindle pitch: 260mm×260 mm (Customizable)

Creel number: 8 (Customizable)

Other Parameters

Input voltage: 3 × 380V ±10%

Input frequency: 50Hz ±5%

Installed capacity: 35KVA (standard)

Air supply: 0.3L, 6Mpa

Main machine weight: 5500kg

Creel weight: 2500kg

Idle running noise: ≤80dB