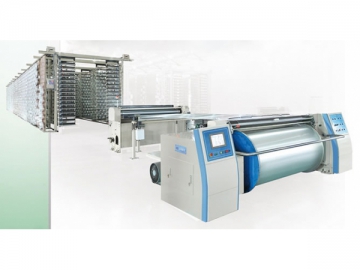

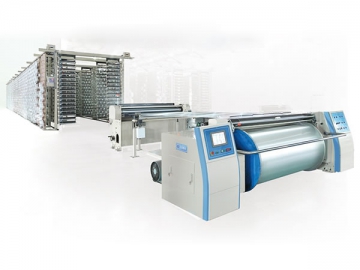

Warping Machine, JT500

Warping Machine | Textile Warping Process Prepreration | Warping Speed 600m/min, Winding Width 1780mm (customizable)

It comes with a press roller to make the yarns wound around the beam keep flat and smooth. The press roller realizes flexible contact with the yarns and is designed an instant inversion structure that avoids fluffing at emergency stop. In addition, the warping machine is provided with hairiness testing system and automatic stop device at yarn breakage. It is now a commonly used weaving preparation solution.

Pressure Control Cabinet

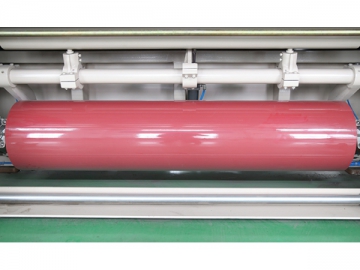

Pressure Control Cabinet Press Roller

Press Roller Pressure Gage

Pressure GageFeatures of the Warping Machine

1. Assembly

The textile machinery is manufactured using a strict assembly technology. It realizes dust-free assembly on a special assembly platform, thus ensuring high speed and high quality of the warper.

2. Winding Tension Control Unit

a. Guide roller system: two aluminum alloy yarn guide roller with magnetic powder brake to control winding tension.

b. Rubber roller tension control system: When the warper starts up, the rubber roller rises to press the yarns on the tension roller.

c. Above-mentioned winding tension control methods can be preset on the touch screen.

3. Hairiness Detector (Optional)

The hairiness detector can warn the worker to handle heavily hairy problem on the yarns, so as to further improve yarn quality.

4. Safety Device

The warping machine employs dual safety device, in order to better protect the screw rod.

5. Leasing Reed

The reed comes with the up to date design. Assembly of aluminum oxide and yarn guide plate can dramatically extend reed's service life.

6. Group Creeling

Under the condition that it will not affect the production, the warping machine can realize group creeling that is conducted on the outer side. When it needs creeling, just turn the creel stand 180 degree.

7. Auto-Stop Device

The weaving machinery is designed with an auto stop device for yarn breakage. At contact moment, the voltage can be reach about 500V, thus ensuring quiet reliable performance.

| Winding width | 1780mm (Customizable) | |

| Warping speed | 600m /min | |

| Yarn roll diameter (beam dia .) | Φ 1000mm (standard ) Φ 800mm, Φ 920mm optional | |

| Winding tension | Max. 50kg | |

| Drive motor | AC vector motor | |

| Loading and doffing system | Automatic loading and doffing controlled by motor and starting device | |

| Tension control | Controlled by magnetic powder brake and press roller Optional: AC vector motor and rubber roller | |

| Reed | Precise assembly of aluminum oxide and yarn guide plate | |

| Safety device | ● | |

| Photoelectric monitor | ● | |

| Beam diameter preset | Manual | - |

| Touch screen | ● | |

| Waxing device | ● | |

| Hairiness detector | ● | |

| Creel thread breakage auto-stop device | ● | |

| Creel first row anti-static system | ● | |

| Creel back row anti-static system | ● | |

| Creel roll thread guide plate double-ply design | ● | |