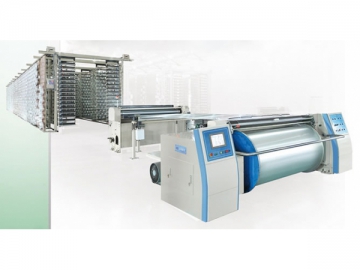

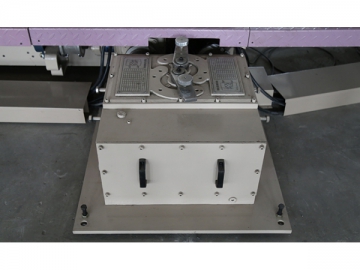

Sizing Machine, JT500

Sizing Machine in Textile | Textile Industry Equipment | Max. Sizing Speed 400m/min, Working Width 1900mm

This sizing machine adopts low tension control method without transmission shaft, making the control range more extensive, and more stable when accelerating or decelerating. Drying room and heating cylinder can keep constant temperature to achieve the optimum drying effect, and beam cooling device ensures the top quality yarns. This can greatly improve the efficiency of looms.

Transmission shaft

Transmission shaft Leasing rod

Leasing rod Pressure gage

Pressure gage Sizing machine (the side without transmission shaft)

Sizing machine (the side without transmission shaft)Features

1. Shaft free low tension control makes control range wider and ensures stable control.

2. Excellent electronic control system ensures stable A/B elongation.

3. Tension at accelerating or decelerating is stably controlled, producing the most superior yarns.

4. The high speed sizing machine is equipped with beam cooling device to improve the quality of sized yarns.

5. It realizes the best drying effect by means of drying oven and heating cylinder which can maintain constant temperature.

6. Hot air circulating system is controlled by a frequency converter, thus providing the optimal air supply effect.

7. The dryer can execute drying to maximum 6 layers of yarns and thereby increase drying efficiency.

8. The automatic sizing machine can recycle the exhausted air from the dryer and left heat inside it. In this way, it can reduce the consumption of steam.

9. Special heat insulation structure of the drying room remarkably improves drying efficiency.

| TYPE | |

| Max. sizing speed | 400m /min |

| Working width | 1900mm |

| Sizing rollers | 1900 |

| Elongation control method | Multi-section drive method |

| Sizing method | Double squeezing roller |

| Immersion roller diameter | Φ 190mm |

| Sizing roller diameter | Φ 230mm |

| Squeezing roller diameter | Φ 220mm |

| Squeezing roller structure | Even squeezing roller |

| Max. squeezing load | 15KN |

| Drying method | Circulating hot air and heating cylinder |

| Temperature control | Automatic temperature control system |

| Number of cooling device | 4 4 |

| Drying oven length | 5 5 |

| Electric heating | 45 27 |

| Number of heating cylinder | 5 |

| Waxing unit | Waxing roller |

| Cooling system | Air circulation |

| Drive motor | EUROTHERM AC vector motor |

| Winding tension control method | AC vector motor feedback control |

| Winding tension control range | 8-50kg |

| Dryer standard configuration | High efficiency hot air supply device with filter; frequency converter |

| Air conditioning in the cooling chamber | Standard configuration |

| Air conditioning for creel | Standard configuration |

| Yarn breakage sensor | Standard configuration |

| Tension automatic detector in drying oven | Standard configuration |

| Steam filling amount | 800kg /h |

| Steam consumption | 600kg /h |

| Total length | 23,165mm |