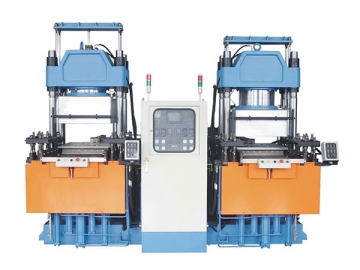

Rubber Injection Molding Machine

Rubber Injection Molding Machine, Rubber Molding Machine, Rubber Injection Press, Rubber Forming Machine, Rubber Injection Machine

The XZL series rubber injection molding machine features 4-post structure, mainly comprised by pre-heating, injection, clamping, movable platen, and ejection units. Supporting parts like hydraulic system, heaters, and control system are included, among which the control system is consisted of PLC programmable controllers and LCD touchscreen. With compact structure, reasonable layout, high rubber injection efficiency, and uniform heating result, the rubber injection press is competent in forming various complex-shaped products. XZL series injection molding machine is applicable in dealing with different rubbers like natural rubber and synthetic rubber. It has passed the CE certification.

Details of XZL Series Rubber Injection Molding Machine

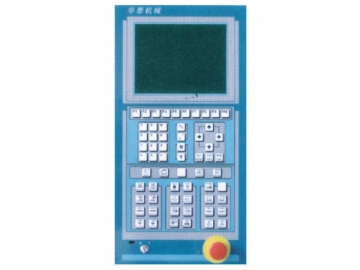

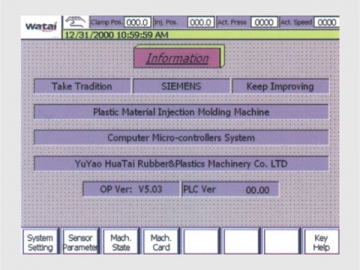

1. Control System

● There are 3 optional computer control systems: Siemens system, Techmation system, and Mitsubishi system

● Parameters are displayed intuitively and can be set easily

● Super-twisted nematic display is adopted

● The control system of the rubber molding machine allows the system to store several groups of mold parameters

● The real time multi-tasking operation system makes it easy for users to conduct remote diagnostics via personal computers

● The whole working process of the equipment is in monitoring to ensure its safe running. Both self-diagnosis and auto alarming functions are available

● Language selection: English, Chinese, Japanese

● Standard card slot

● High speed dual-core processor

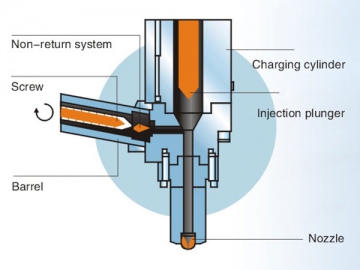

2. Stable Injection System

● Standard and modular design

● The feeding and injection system of the rubber injection machine is suitable for rubbers with different hardness

● The accuracy and stability of the rubber injection process is powerfully ensured with the displacement sensing system and high-precision mechanical components

● An extremely small back pressure it set to ensure the rubber weighing accuracy

● With a reasonable injection channel, the rubber residue and the loss of injection force is lowered to the min

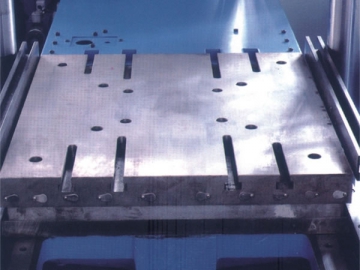

3. High Strength Clamping Unit

● The deformation of the clamping unit, which has been proved by finite element stress analysis and CAD modeling, is less than 0.1mm under certain load

● For the rubber injection molding equipment, the clamping process is conducted efficiently under the help of 2 supporting cylinders, with the clamping force working through a master cylinder. In this way, we can both guarantee the operation consistency and save the time. The efficient exhaust system, combined with the elaborately-designed channel, will ensure that the gas generated during the vulcanization process is fully exhausted.

● The mode is adjusted gradually in the whole injection process to ensure the accuracy and safety.

4. Silicone Rubber Feeding Device

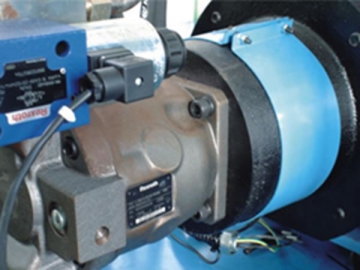

5.Reliable Cycling System

The variable displacement pump from Bosch Rexroth provides a powerful guarantee for the cycle running of the system.

6. Temperature Regulator

The temperature regulators set at different parts of the injection press has saved the energy and cut on the costs largely.

Customization Service

With 51 years' equipment manufacturing experience, we know exactly what our clients want, and provide customization service to meet their diversified requirements.

1. The machine structure is optional (horizontal/vertical).

2. Machine color is customizable.

3. Clients have access to specify the exact kind of components they want, or predetermine some technical parameters like dimension of platens, clamping force, and injection volume, etc.

4. What our clients need to do is only to provide their drawings, and communicate and determine some details with our engineers, and leave the left work to us. Supported by 20 technical engineers who have over 20 years' working experience, we are competent in providing you the exact rubber injection molding machine you want.

| Model | XZL-600×1500 | XZL-1000×2000 | XZL-1500×2000 | XZL-1500×2500 | XZL-2000×2500 | XZL-2000×3000 | XZL-2500×3000 | XZL-4000×5000 | |

| Injection unit | Injection capacity (cm³) | 600 | 1000 | 1500 | 1500 | 2000 | 2000 | 2500 | 4000 |

| Injection pressure (MPa) | 156 | 157.5 | 170 | 170 | 170 | 170 | 133 | 1560 | |

| Injection speed (cm³/s) | 80 | 95 | 85 | 85 | 110 | 110 | 106 | 120 | |

| Plunger diameter (mm) | 55 | 60 | 70 | 70 | 80 | 80 | 90 | 110 | |

| Screw diameter (mm) | 40 | 40 | 50 | 50 | 50 | 50 | 50 | 50 | |

| Screw length /diameter (L/D) | 12.5: 1 | 12.5: 1 | 11.5: 1 | 11.5: 1 | 11.5: 1 | 11.5: 1 | 11.5: 1 | 11.5: 1 | |

| Clamping unit | Clamping force (KN) | 1500 | 2000 | 2000 | 2500 | 2500 | 3000 | 3000 | 5000 |

| Stroke (mm) | 400 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | |

| Intervals between platens (mm) | 500 | 500 | 500 | 500 | 500 | 650 | 650 | 700 | |

| Min mold thickness (mm) | 100 | 50 | 50 | 50 | 50 | 200 | 200 | 250 | |

| Platen dimension (mm) | 450×480 | 480×550 | 480×550 | 480×550 | 480×550 | 650×720 | 650×720 | 750×850 | |

| Other parts | Motor power (kw) | 11 | 15 | 15 | 15 | 15 | 15 | 15 | 22 |

| Heating power of platens (kw) | 9 | 12 | 12 | 12 | 12 | 18 | 18 | 18 | |

| Dimension (m) | 2.0×1.55×3.3 | 2.0×1.6×3.8 | 2.0×1.6×3.8 | 2.0×1.6×3.9 | 2.0×1.6×3.9 | 2.2×2.1×3.8 | 2.2×2.1×3.8 | 3.1×1.4×5.1 |

After Sales Service

1. A free replacement is available for those broken parts under normal use for a period of 1 year from the date of delivery.

2. For the consumable parts, clients can either ask them to be delivered accompanied with the rubber injection equipment or sent by express.

3. All of our after sales service personnel have accumulated more than 10 years' experience and are familiar with the equipment in Huatai. Upon users' request, we can send professionals to the production site to install or check the equipment until the machine can run normally.