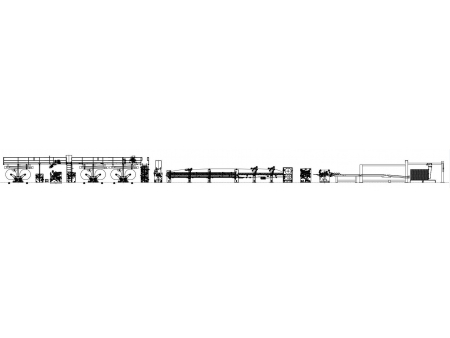

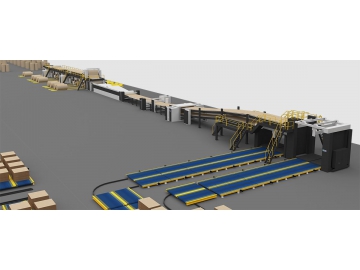

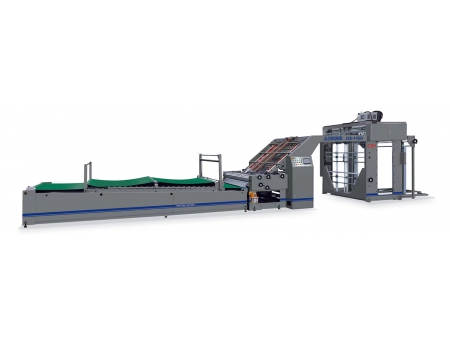

Corrugated Cardboard Production Line (Multi-Layer)

Depending on the size and scale of your project, our multi-layer corrugated cardboard production line features a variety of machines that operate conveniently at adjustable speeds, including mill roll stands, corrugated rollers, core paper preheaters, glue machines, slitters, and auto stackers.

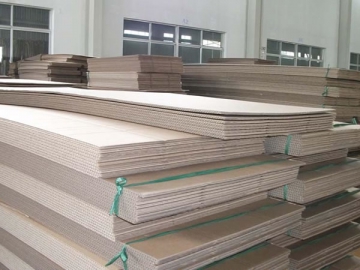

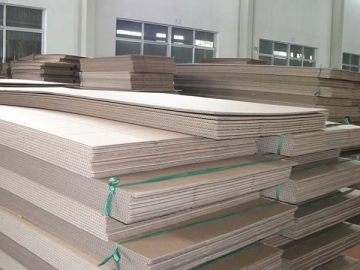

Output sample of the corrugated cardboard production line| No | Design speed | Model | Working width |

| 1 | 150m /min | 3 layer 5 layer False 7 layer 7 layer | 1400mm 1600mm 1800mm 2000mm |

| 2 | 180m /min | 3 layer 5 layer False 7 layer 7 layer | 1400mm 1600mm 1800mm 2000mm |

| 3 | 200m /min | 3 layer 5 layer False 7 layer 7 layer | 1400mm 1600mm 1800mm 2000mm 2200mm |

| 4 | 260m /min | 3 layer 5 layer False 7 layer 7 layer | 1800mm 2000mm 2200mm |

| Note: the false seven layer means five layers corrugated cardboard production line but three single face to meet different customer more flutes requirement. | |||

Detailed information of the corrugated cardboard production line

Single Machines Introduction of Cardboard Production Line

Mill Roll Stand

Mill Roll StandYZJ1/2 Hydraulic Mill Roll Stand

1)Holding diameter max/min: Ф1500mm / Ф300mm

2)Max. holding paper weight: 2500kg

3)Range of Width: 1400-2000 mm

4)CNC machining ensures high precision.

5)Hydraulic electric valves from Taiwan, hydraulic motor pump head from Japan, low voltage components from Schneider.

YZJ3 Hydraulic Mill Roll Stand

1)Holding diameter max/min: Ф1600mm/Ф320mm

2)Maxx holding paper weight: 3500kg

3)Range of Width:2200mm

4)CNC machining ensures high precision.

5)Hydraulic electric valves from Taiwan, hydraulic motor pump head from Japan, low voltage components from Schneider.

Twin Corrugated Rollers for Single-Sided Cardboard

Twin Corrugated Rollers for Single-Sided CardboardSDW3 Twin Corrugated Rollers Single Face Machine

1)Design speed 220m/min.

2)Working width: 1800-2200mm.

3)The machine can change either set of corrugated rollers within 15-30 seconds and recover normal production in 2-3 minutes.

4)Two sets of corrugated rollers in one unit are made of chromed and tungsten carbide and are easy to replace.

5)Corrugated roller uses a rotary structure, hydraulic power to drive, and oil cylinder to lock. Changing the type of corrugated rollers mid-operation won't cut the surface paper.

6)Operator can replace any set rollers within two minutes without stopping the machine.

7)When one set of corrugated rollers is working, the other set runs at a low speed to save energy.

DW Series Single Face Machine

DW Series Single Face Machine1)Design speed: 150m/min, 200m/min, 260m/min

2) Working width:1400-2200mm

3)CNC machining ensures high precision.

4)Glue thickness can be adjusted automatically according to the machine's speed.

5)When the paper breaks, an electric eye tracking device automatically decreases speed.

6)PLC and inverter from Taiwan, reduced speed motor from CPG, low voltage components from Schneider.

Surface Paper Preheater

Surface Paper PreheaterMY1 Surface Paper Preheater

1)Diameter: 900mm / 1000m.

2)Working width: 1400-2000mm.

3)The heating area uses electrical adjustment.

4)The preheater uses national standard pressure vessel with an inspection certificate.

5)Steam trap from Taiwan.

MY2 Surface Paper Preheater

1)Diameter: 900mm / 1000m.

2)Working width: 1400-2200mm.

3)The heating area uses electrical adjustment.

4)Heating cylinder run by electric motor.

5)The preheater uses national standard pressure vessel with an inspection certificate.

6)Steam trap from Taiwan.

Core Paper Preheater

Core Paper PreheaterXY1 Core Paper Preheater

1)Diameter: 900mm / 1000m.

2)Working width: 1400-2000mm.

3)Heating area uses electrical adjustment.

4)The preheater uses national standard pressure vessel with an inspection certificate.

5)Steam trap from Taiwan.

XY2 Core Paper Preheater

1)Diameter: 900mm / 1000m.

2)Working width: 1400-2200mm.

3)Heating area adopts electrical adjustment.

4)Heating cylinder run by the electric motor.

5)The preheater uses national standard pressure vessel with an inspection certificate.

6)Steam trap from Taiwan.

Over Convey Bridge

Over Convey BridgeGQ3 Over Convey Bridge

1)The conveyer feeds paper from the single face machine to the glue machine.

2)Main frame made of quality steel.

3)Guardrail adapted from Germany.

4)Inverter motor adjusts wind absorption volume for the paperboard tension.

5)Work speed 150m/min, working width 1400-2000mm.

GQ4 Over Convey Bridge

1)The conveyer feeds paper from the single face machine to the glue machine.

2)Main frame made of quality steel.

3)Guardrail adapted from Germany.

4)Inverter motor adjusts wind absorption volume for the paperboard tension.

5)Work speed 200m/min, 260m/min,working width 1400-2200mm.

Optional Convey Bridge Aligner

Optional Convey Bridge Aligner

Optional Convey Bridge Aligner1)Module structure for easy installation and repair.

2)Automatically adjust top, middle and bottom layers to align.

3)Full width infrared light curtain aligns based on paper edge or middle.

4)The paper tension controller automatically controls paper without tearing it.

5)Reduced noise, fast, and energy-saving.

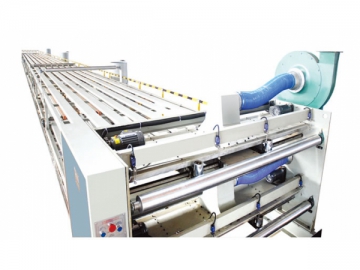

Double Face Machine

Double Face MachineSM3 Double Face Machine

1)Heating unit and cooling unit uses concentrated press rollers to ensure moulding quality.

2)Pressure vessel uses first grade products.

3)Hydraulic lifting.

4)Top cotton belt uses automatic correcting error device and high quality components from domestic brands for long service life.

5)Working speed 150m/min, working width 1400-2000mm.

SM4 Double Face Machine

SM4 Double Face MachineSM4 Double Face Machine

1)Heating unit and cooling unit uses concentrated press rollers to ensure moulding quality.

2)Pressure vessel uses first grade products.

3)Hydraulic lifting.

4)Top cotton belt uses automatic correcting error device and high quality components from domestic brands for long service life.

5)Working speed 200m/min, 260m/min, working width 1400-2200mm.

ZQY Slitter Scorer

ZQY Slitter Scorer1)CNC machining ensures high precision.

2)Super thin blade separates paper, automatically or manually with a sharp knife.

3)Ball screw drives with high mechanical positioning and reliability.

4)Slitter speed uses an inverter motor with frequency conversion control, AC servo motor, and imported specialized driver.

5)The dividing paper size and pressing line size uses electric motor to adjust within 3-8 seconds.

6)The slitter scorer can input up to 999 sets of size.

7)Speed of 150m/min, 200m/min, 260m/min, working width of 1400mm-2200mm.

Single layer cut off machine

Single layer cut off machine Double layer cut off machine

Double layer cut off machineHQ2 Screw Blade NC Cutters

1)Processes single layer or double layers.

2)CNC machining ensures high precision.

3)The cut off machine uses an AC servo motor and imported specialized driver.

4)Spiral knife made from long lasting material.

5)High precision gears.

6)The length of the cut paper is 400mm-9999mm; cutting precision is ±1mm.

7)Working speed of 150m/min, 200m/min, working width 1400mm-2200mm.

HQ3 Screw-Blade NC Cutters

1)Processes single layer or double layers.

2)CNC machining ensures high precision.

3)The cut off machine uses an AC servo motor and imported specialized driver.

4)Spiral knife made from long lasting material.

5)High precision gears.

6)The length of the cut paper is 500mm-9999mm; cutting precision is ±1mm.

7)Working speed of 260m/min, working width 1400mm-2200mm.

DM1 Manual Stacker

DM1 Manual Stacker

DM1 Manual Stacker2)Automatic tracking production schedule, speed can be adjusted.

3)90 degree turning with electric drum shifting transmission.

4)Max. stacking length: 3000mm.

5)Effective speed: 150m/min.

6)Working width: 1400-2000mm

DM2 Auto Stacker

DM2 Auto Stacker

DM2 Auto StackerDM3 Automatic Hanging Basket Stacker

1) This stacker features computer-controlled servo motor and lifter unit, uniform movement, and neat stacking in hanging baskets.

2) Stacking features adjustable speed, automatic control, high efficiency and reduced labor.

3) Independent conveyor belts feature four frequency motor control and automatic speed change transmission according to production speed.

4) Suction-fed paper makes for stable stacking.

5) Max. speed of 200-260m/min, working width of 1400~2200mm.

Related names:

Corrugated fiberboard equipment | Paperboard processing machine | Corrugated cardboard production solution