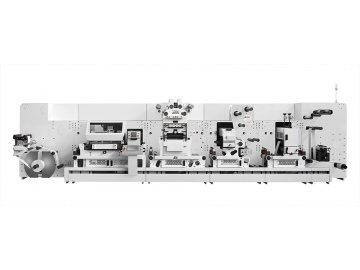

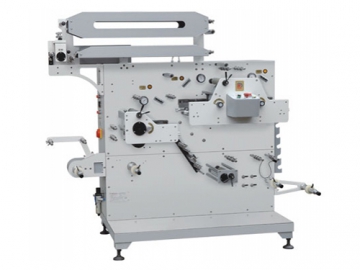

Flexo Printer Slotter (Semi-Automatic)

There are four models of the semi-automatic printing slotting machine available for customers to choose from. The maximum range of processing cardboard is 1400 x 2700mm, and can carry out 3-7 layers of corrugated conduct operations. This machine is a semi-ink printing machine, with two to four color options for printing.

Performance Parameters of the Main Mechanism

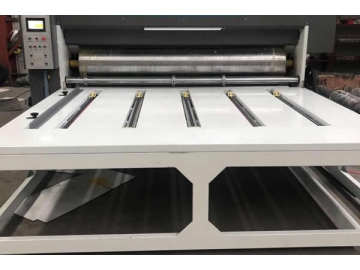

1.Paper feeding: chain, paper pushing feeding

2.The open and closing process of the unit uses electrical walking and pneumatic locking (with overload protection function).

3.Paper feeder roller: the upper axle uses a ginning paper feeding wheel, while the lower axle uses a steel ginning roller. The surface and its hard chromium plating ensures the smooth feeding of the paper board and does not damage the corrugated cap.

4.Printing roller: Customers can use an advanced, convenient and practical hanging plate with hooked slots (optional). Loading and unloading of the plate can be independently controlled by the pedal switch. The phase adjustment uses a non-stop working process, 360º electrical and numerical adjustment, and input date as per the error and adjustments are done automatically.

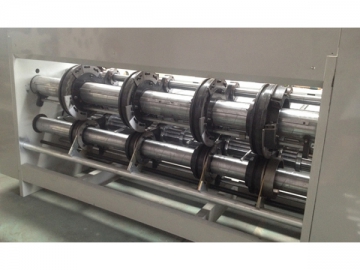

Ink Circulating System

1.The anilox roller uses steel material (180#,-240#). Customers can choose according to their requirements, and choose the after balance and hard chrome plating.

2.The rubber roller is made of natural oil proof, acid proof and alkali proof rubber.

3.Pneumatic diaphragm pump inking, and automatic circulating. After adding water, automatic cleaning is carried out.

4.A stop working process is used to distribute the ink. This process, and the ink circulation system work together.

5.The ink circulation system consists of anilox and rubber rollers that are controlled using a pneumatic control system. A fat lifting process can print small script, fine patterns or different color processes. It can make the printed matter clear, full and round.

Slotting Part (Optional)

1.The slotting part can electrically adjust the phase by 360º.

2.Users can manually adjust the height of the carton, and the four knives are synchronous.

3.Long and wide adjustment, loading and unloading of the knife disc, upper and lower creasing, paper kicking knife. The pointer on the scale can be manually and automatically moved to save time.

4.Pneumatic and combined control of the entire machine carries out counting, alarming and operating on the back of the machine.

| Parameter name | Unit | Model size | |||

| Economic speed | pieces/min | 60 | |||

| Max. feeding size | mm | 1400 × 2000 | 1400 × 2200 | 1400 × 2400 | 1400 × 2700 |

| Min. feeding size | mm | 350 × 650 | |||

| Max. printing size | mm | 1400 × 1900 | 1400 × 2100 | 1400 × 2300 | 1400 × 2600 |

| Color accuracy | mm | Double colors ± 0.5 three colors ± 0.6 four colors ± 0.75 | |||

| Fitting printing cardboard thickness | 3-7Ply cardboard | ||||

| Min. slotting distance | mm | 250 × 60 × 250 × 60 | |||

| Max. slotting depth | mm | 340 | |||