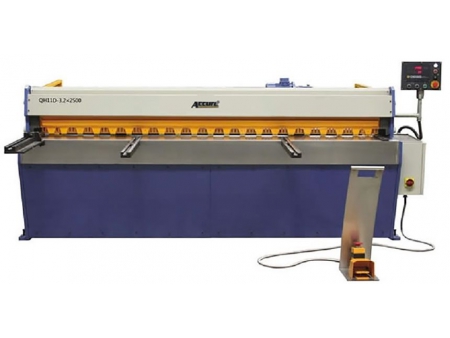

Hydraulic Guillotine Shear

Request a Quote

QC11Y Series

Features

- Totally EU streamlined design, monoblock by welding robots & aparatus and stress relief process by Annealing treatment.

- The cutting beam of hydraulic guillotine shear has been designed in inner-inclined structure with adjustable cutting angle and blade gap.

- The upper beam is able to move on the linear guide under the push of cylinder, to realize the shearing action.

- Standard subsection blade with 4 cutting edges, quality high-carbon high-chrome blades D2 quality.

- This guillotine shearing machine adopt integrated hydraulic system, more reliable and easy for maintenance. and the hydraulic system from Bosch-Rexroth, Germany,

- This sheet metal cutting equipment adopts three point supporting type rolling guideway to raise shearing precision.

- CE conformity including tiltable fornt finger guard and optical rear safety guard,

- High quality shear blades, service kit, colours are light/dark grey and yellow.

Standard Equipment

- Rapid and precise blade clearance adjustment by handwheel on the side frame

- Multi edge blades for cutting aluminium, mild steel and stainless steel

- Cutting line illumination and wire for shadow line cutting

- Counter of strokes, cutting length adjustment

- The sheet metal shear uses hydraulic and electrical overload protection

- Squaring arm and front support arms

- Bed infill plates with ball transfers

- Adjustable sound angle & blade gap

- The hydraulic guillotine shear adopt Delta inverter with ball screw and polished rod with 0,01 mm accuracy.

Estun E21s NC Control system

- Monochrome LCD box panel.

- Integral factor programmable freely

- Automatic positioning control

- Spindle allowance offset

- Internal time relay

- Stock counter

- Backgauge position display, resolution in 0.01mm

Specifications

| Model (AC/MS8) | QC11Y-6×3200 | QC11Y-8×3200 | QC11Y-10×3200 | QC11Y-12×3200 | QC11Y-12×4000 | |

| Cut Thickness | mm | 6 | 8 | 10 | 12 | 12 |

| Cut Thickness | mm | 3200 | 3200 | 3200 | 3200 | 4000 |

| Shear Angle | Degree | 0.5 ° -2.5 ° | 0.5 ° -2.5 ° | 0.5 ° -2.5 ° | 0.5 ° -2.5 ° | 0.5 ° -25° |

| SPM | min-1 | ≥ 15 | ≥ 15 | ≥ 15 | ≥ 6 | ≥ 6 |

| Back Gauge | mm | 20-600 | 20-600 | 20-600 | 20-800 | 20-1000 |

| Throat Depth | mm | 100 | 100 | 100 | 100 | 100 |

| Main Motor | kW | 7.5 | 11 | 11 | 18.5 | 30 |

| Net Weight | kg | 6200 | 8000 | 8000 | 12000 | 21000 |

| Outline Size | mm | 3740×1680×1750 | 3740×1750×1750 | 3850×1750×1850 | 3850×1950×2300 | 4200×2380×2970 |

| Model(AC/MS8) | QC11Y-12×6000 | QC11Y-16×3200 | QC11Y-16×4000 | QC11Y-16×6000 | QC11Y-16×8000 | |

| Cut Thickness | mm | 12 | 16 | 16 | 16 | 12 |

| Cut Thickness | mm | 6000 | 3200 | 4000 | 6000 | 4000 |

| Shear Angle | Degree | 0.5 ° -2.5 ° | 0.5 ° -2.5 ° | 0.5 ° -2.5 ° | 0.5 ° -2.5 ° | 0.5 ° -2.5° |

| SPM | min-1 | ≥ 8 | ≥ 12 | ≥ 10 | ≥ 6 | ≥ 5 |

| Back Gauge | mm | 20-1000 | 20-1000 | 20-1000 | 20-1000 | 20-1000 |

| Throat Depth | mm | 100 | 100 | 100 | 100 | 100 |

| Main Motor | kW | 18.5 | 18.5 | 18.5 | 22 | 30 |

| Net Weight | kg | 29500 | 13500 | 16300 | 36500 | 75500 |

| Outline Size | mm | 6940×2480×2750 | 3850×2150×2050 | 4650×2150×2250 | 6950×2550×2650 | 9000×3280×3270 |

Detailed Pictures

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos